- NO63, XinTai Road, XinMaLian, DaLang Town, Dongguan City, Guangdong province

- info@baofengmachine.com

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

China Cnc Machine Manufacturer

China Top CNC Milling Supplier & Manufacturer – BAOFENG offers worldwide clients affordable, rapid, high-precision custom CNC Milling center, a variety of materials available to meet the needs of different industries!

CNC machines are used in various industries for precise and efficient machining of complex parts. Both horizontal and vertical CNC machines offer advantages in terms of productivity, accuracy, and flexibility. Horizontal CNC machines are often used for heavy-duty machining and for producing large, complex parts that require multiple machining operations. In contrast, vertical CNC machines are better suited for small to medium-sized parts that require high accuracy and precision.

The choice between a horizontal and vertical CNC machine depends on various factors such as the size and complexity of the workpiece, the type of machining operation required, the production volume, and the available floor space. CNC machines can be programmed to perform multiple operations automatically, making them a popular choice for high-volume production runs.

horizontal and vertical CNC machine

In a horizontal machine, the spindle is placed horizontally, parallel to the ground, and the workpiece is mounted on a table that moves in and out and side to side. The cutting tool is typically mounted on a horizontal arbor and moves across the workpiece in a perpendicular direction. This type of machine is often used for milling, boring, and drilling operations.

In a vertical machine, the spindle is placed vertically, perpendicular to the ground, and the workpiece is mounted on a table that moves up and down and side to side. The cutting tool is typically mounted on a vertical arbor and moves up and down to cut into the workpiece. This type of machine is often used for drilling, tapping, and other operations where a high degree of accuracy is required.

Both types of machines have their advantages and disadvantages, and the choice between them depends on the specific application and the type of workpiece being machined.

BaoFeng Offers Various Types Of The Vertical Machining Center, Cnc Vertical Machining Center , Linear Guide Machining Center , Cnc Horizontal Machining Center, Gantry Type Machining Center, Cnc 5 Axis Machining Center, Vmc Vertical Machining Center, Double Column Machining Center For Customers.and Baofeng Has 12 Years Of Cnc Machine Tool Manufacturing Experience, Providing Customers Worldwide. High-quality Chinese Brand Cnc Machine Tools.

Vertical Machine center

(28)High Precision Machine Center BF-540VP

VSM-540VP is a miniature high-speed and high-precision drilling, milling and tapping machine. It can automatically and continuously perform processing in various processes such as milling, drilling and tapping with one clamping. It is suitable for mirror processing of high-precision copper electrodes, optical parts, lamps and lens molds.

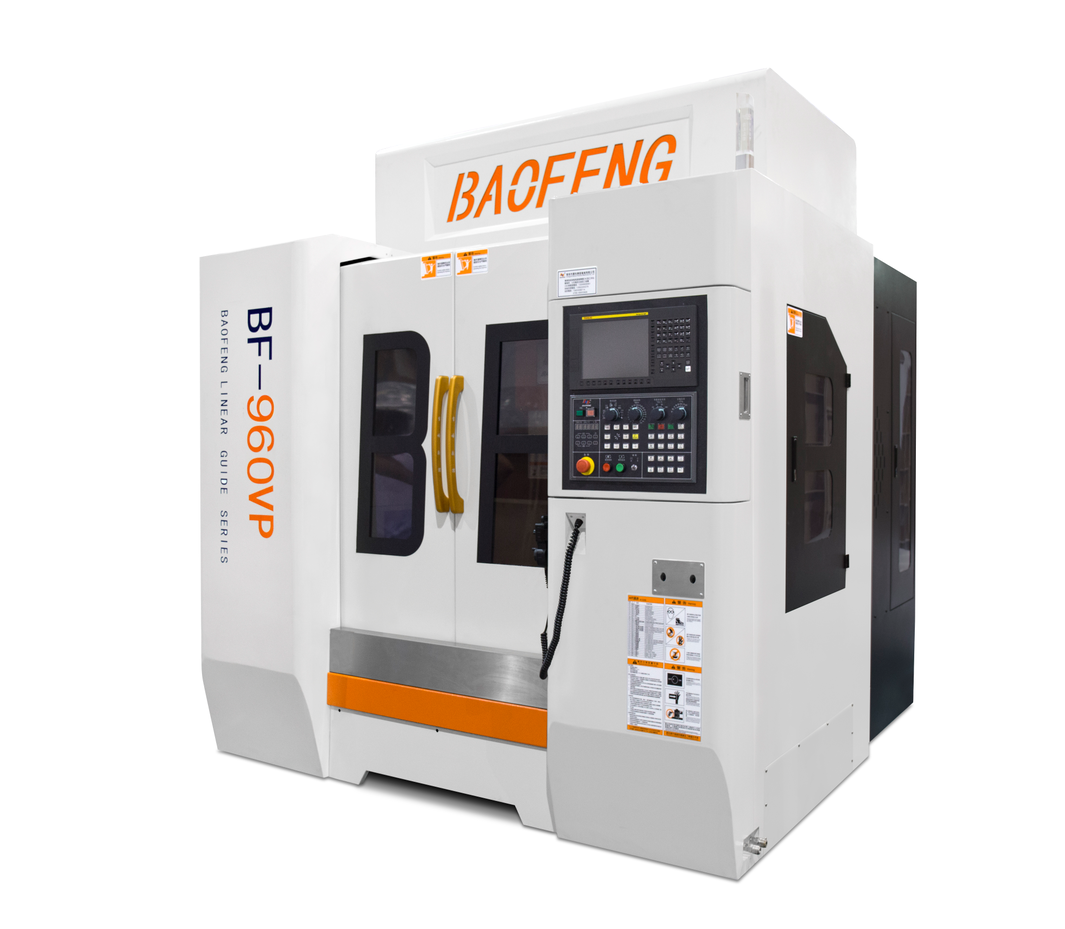

High Precision Machine Center BF-960VP

BF-960VP is a high-speed, high-precision vertical machining center. After one clamping, you can automatically process the workpiece into a variety of processes such as milling and tapping. The machine base and gantry beam are made of Schneeberger mineral casting, which has excellent vibration absorption and very low heat sensitivity and is the preferred bed material for ultra-precision machine tools.

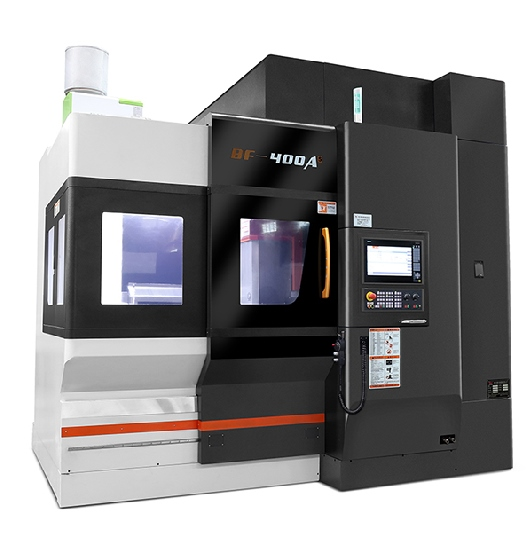

5 axis machine center BF-400A5

The HT300 high-strength castings all have a processing out of the iron crumbs mainly in the form of strips, flakes, low dust ratio and they are processing on steel surfaces with close color. Baofeng machine tool guide rail installation project is done by high precision mother machine milling in advance, and then imported from abroad guide rail grinding machine finishing. Our contact surfaces are higher than those that only rely on grinding machines later and not scraped by hand

Vertical Machine Center BF-850V

BF-850V is a vertical machining center that provides high precision and high power with a very reasonable cost. This machine's features include an ultra-rigid structure, X/Y/Z axis high precision linear guide, ball screw with locking preload design, water cooling system, automatic lubrication system for the spindle shaft, etc. It can be widely used in the automotive, machinery, instrumentation and light industrial textile industries to fully demonstrate high precision and high efficiency machining capability at a very reasonable cost.

Horizontal machine center

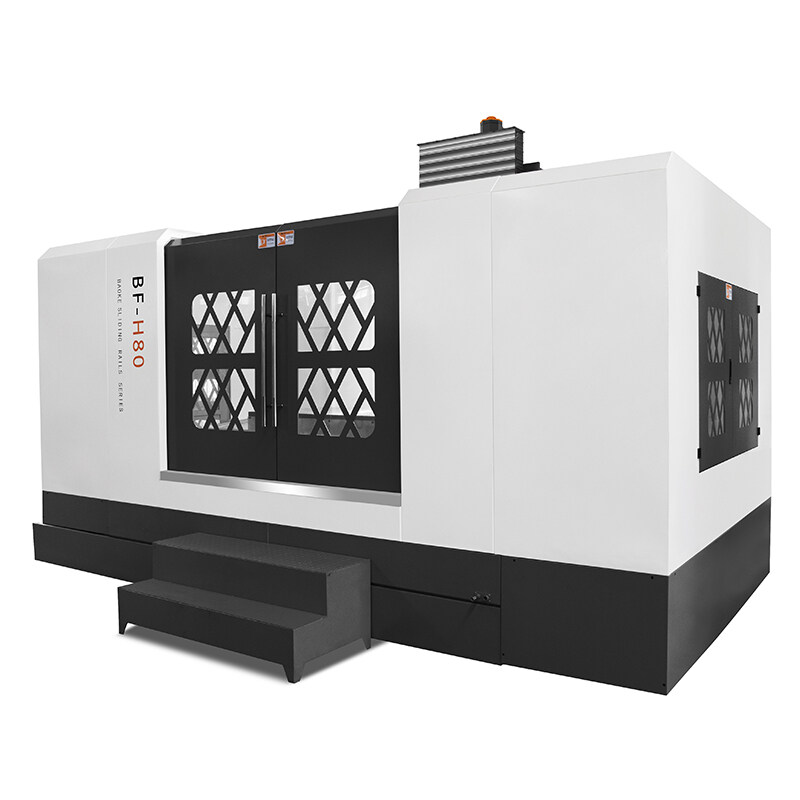

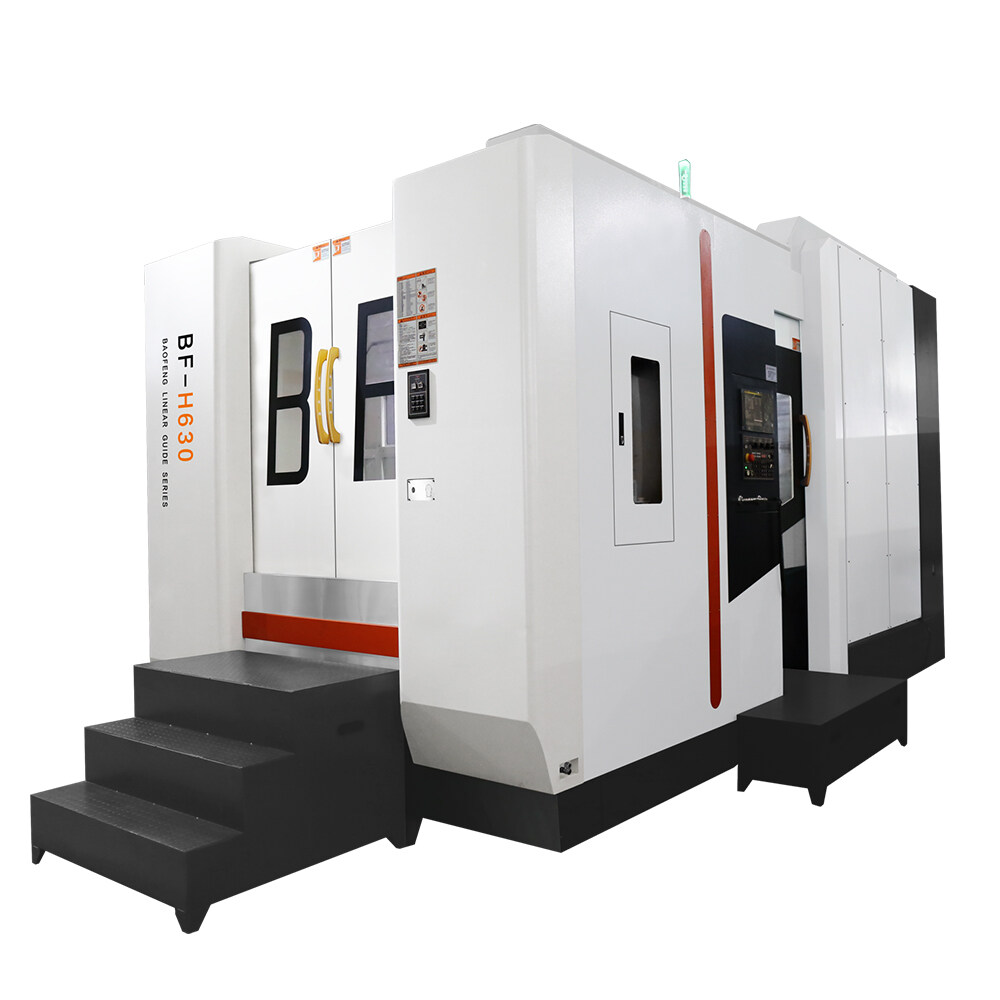

(6)Horizontal Machine Center BF-H80

The HF-H80 Horizontal Machining Center is a high speed, high precision and complete integrated machine tool for processing box, shell and special-shaped parts in automobile, motorcycle, especially auto engine shells and reducer shells. The machine is used in many molding industries to process products with gears such as agricultural machinery and mining machinery etc.

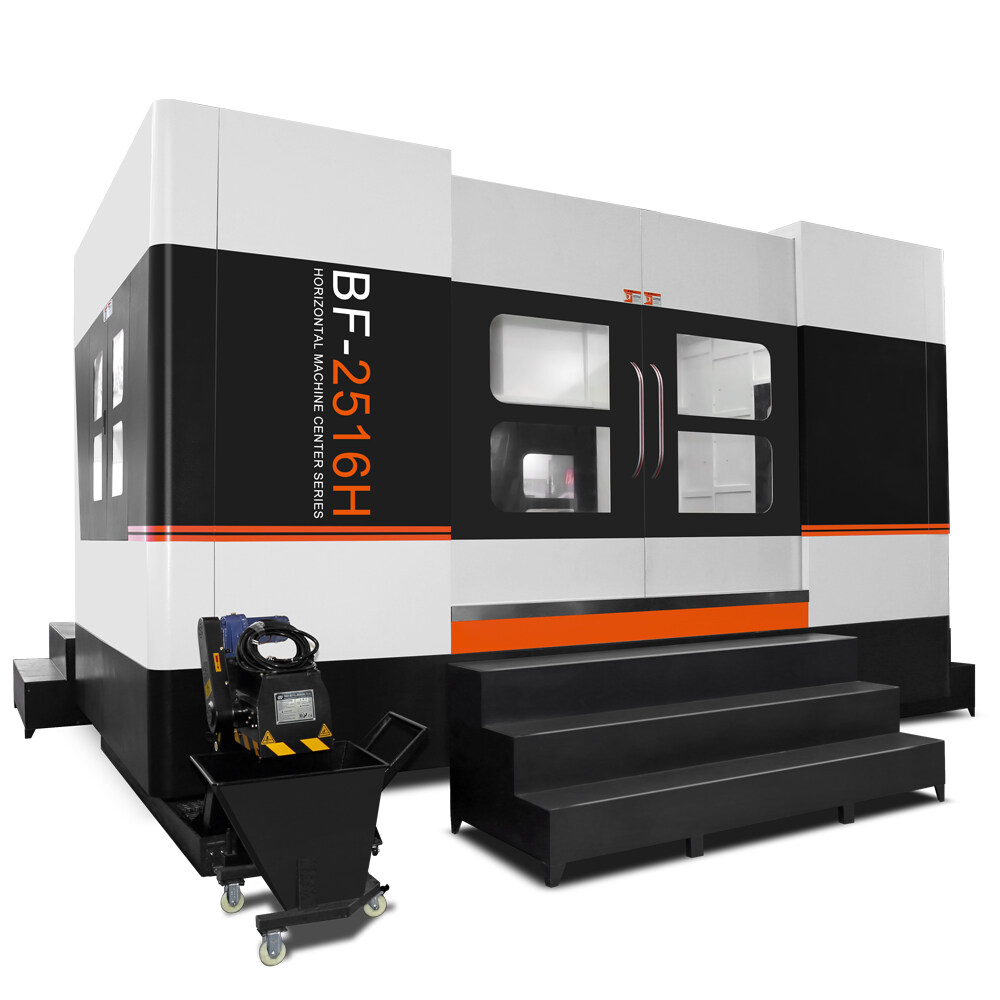

Horizontal Machine Center BK-2516H

With the use of advanced technology, our basic large parts adopt first-class research and development methods such as brand-new mineral materials, three-dimensional synchronous design, FEM finite element analysis, etc. We carry out a reasonable layout to ensure good anti-distortion and anti-bending ability of basic large parts

Horizontal Machine Center BK-1814L

The T-type base, full support structure for each axis, makes the machining accuracy more stable; Large capacity tool magazine and strong processing adaptability. Single and double exchange pallets are optional. Automatic chip removal reduces cleaning downtime. Wide processing range suitable for processing all kinds of mechanical parts

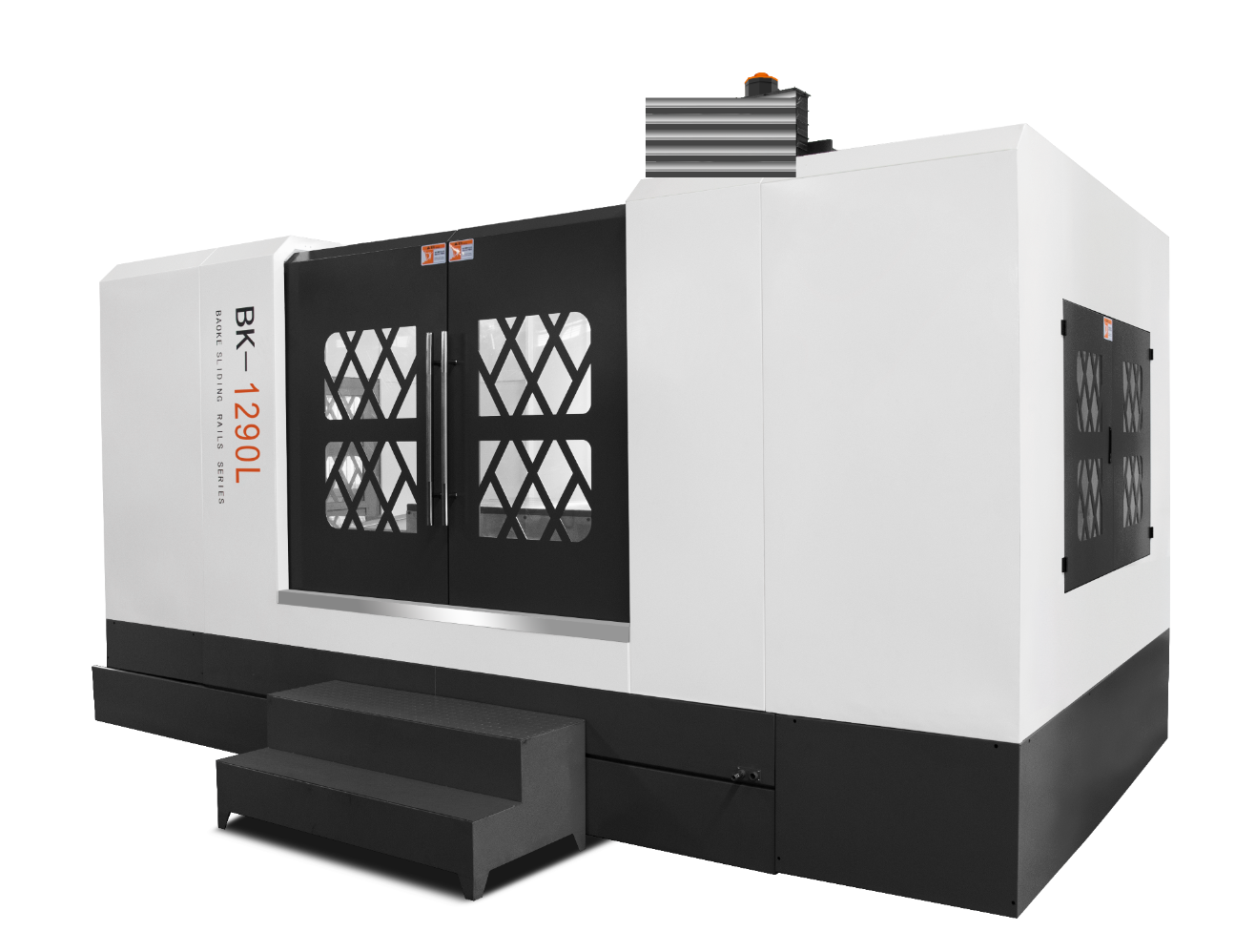

Horizontal Machine Center BK-1290L

The casting material of HT300 is mostly in the form of strips, flakes, low dust ratio and processing surface color close to steel. Our guide rails are more precise than those on the market ground by a milling machine and not scraped by hand. The construction process of every step is standardized, even for each screw. And we have strict inspection standards to inspect the static and dynamic precision of the machine body and whole machines

Double column machine center

(17)BAOFENG BF-8032L Double Column Machining Center

Baofeng CNC Double Column Vertical Machining Centers combine proven machine design with advance technology in control and manufacturing. Reliability and performance make this series a favorite among demanding CNC work shops and in-house productions alike.

BAOFENG BF-6032L Double Column Machining Center

The new CNC Woodworking Machine BF-6032L changes the game in ways that you never thought possible. Portal frame structure, traveling worktable (X-axis), spindle box traveling (Z-axis), saddle traveling on the beam (Y-axis), square ram design and twice speed-reducing with retarders offer low-speed constant torque and high-speed constant power cutting.

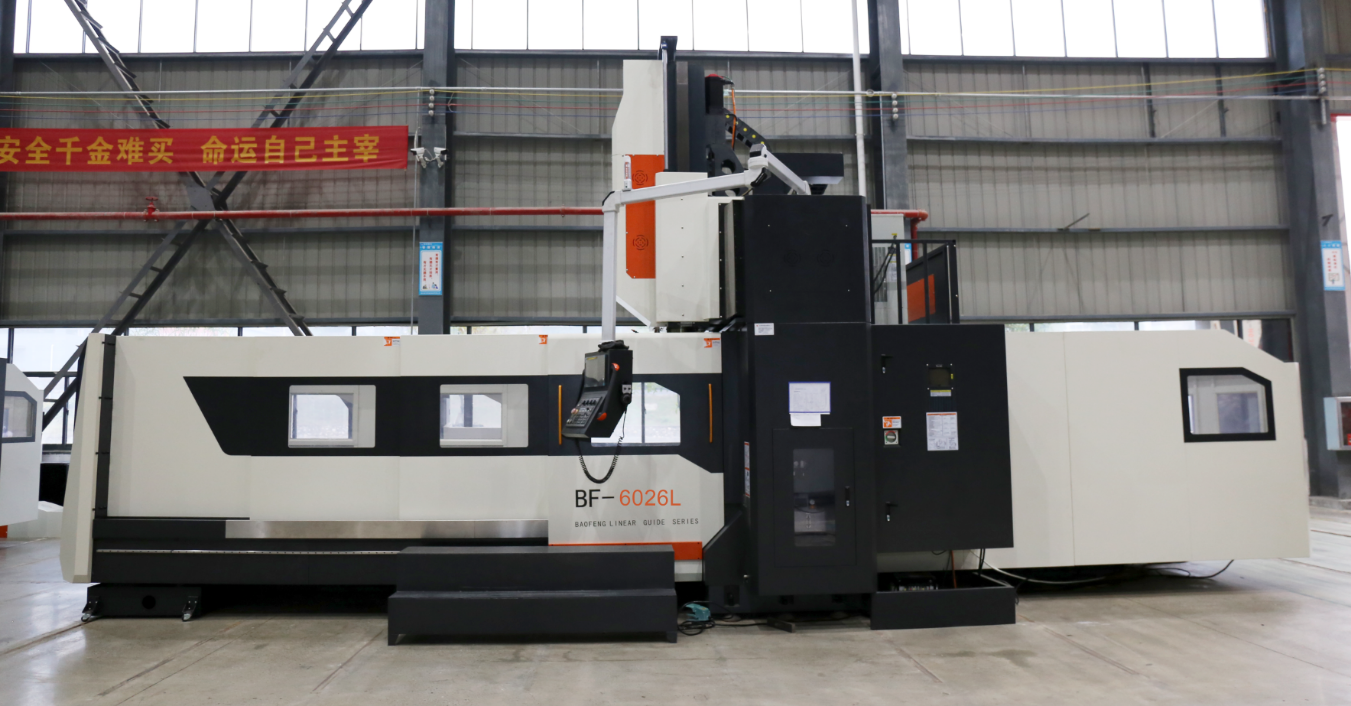

BAOFENG BF-6026L Double Column Machining Center

Double column machining centers are mainly used for the processing of large boxes, complex surface molds, large-shaped parts and plate parts. By adopting international dynamic rigidity design idea and optimizing moving parts on the basic of high rigidity structure symmetry high stability of traditional double column machining center, this series machines are mainly made of base,worktable,columns ,beam ,saddle ,hydraulic system ,lubrication system cooling and filtering system chip device CNC system and other parts.

BAOFENG BF-6029L Double Column Machining Center

We offer Taiwan gear type spindle box and Germany ZF gearbox to realize strong cutting, equipped with Taiwan right angle milling head to realize simple horizontal machining requirements, and equipped with Taiwan universal milling head to realize multiple angle machining requirements. Equipped with automatic pentahedron milling head to realize multiple dimension high precision machining.