- NO63, XinTai Road, XinMaLian, DaLang Town, Dongguan City, Guangdong province

- info@baofengmachine.com

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

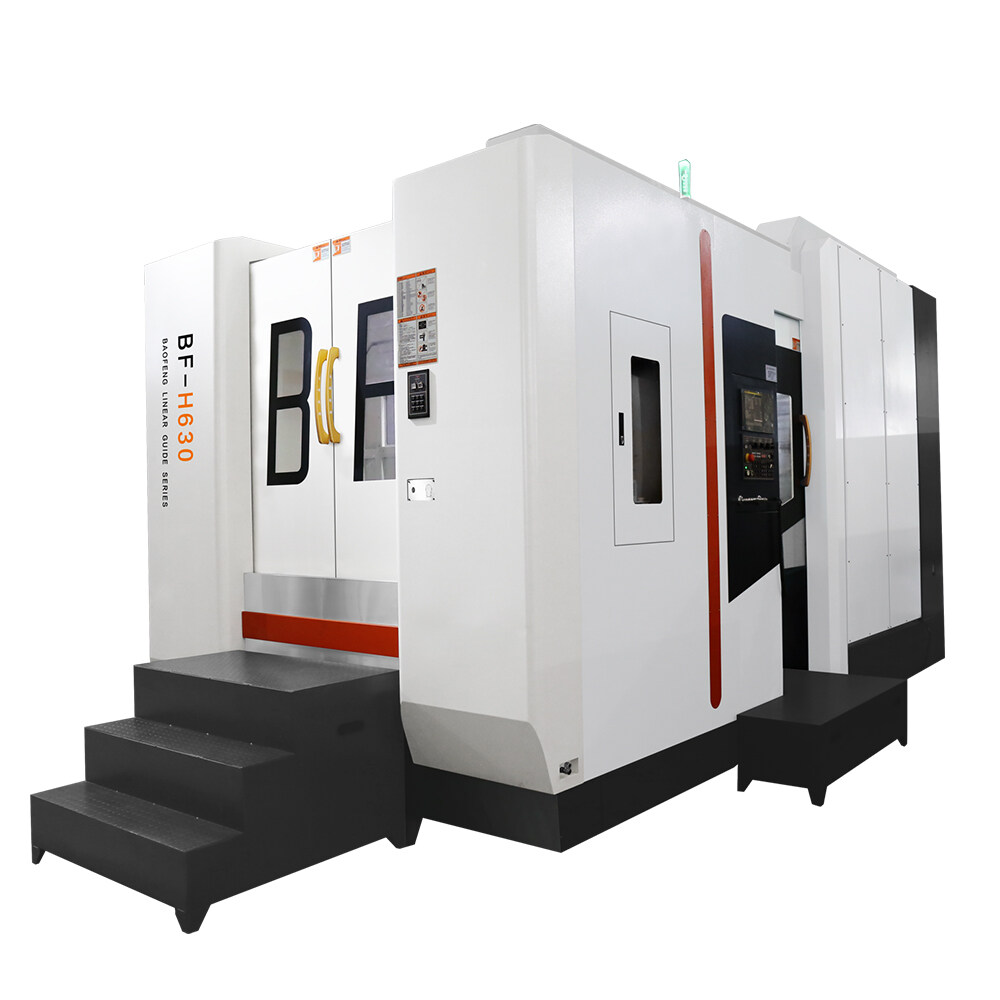

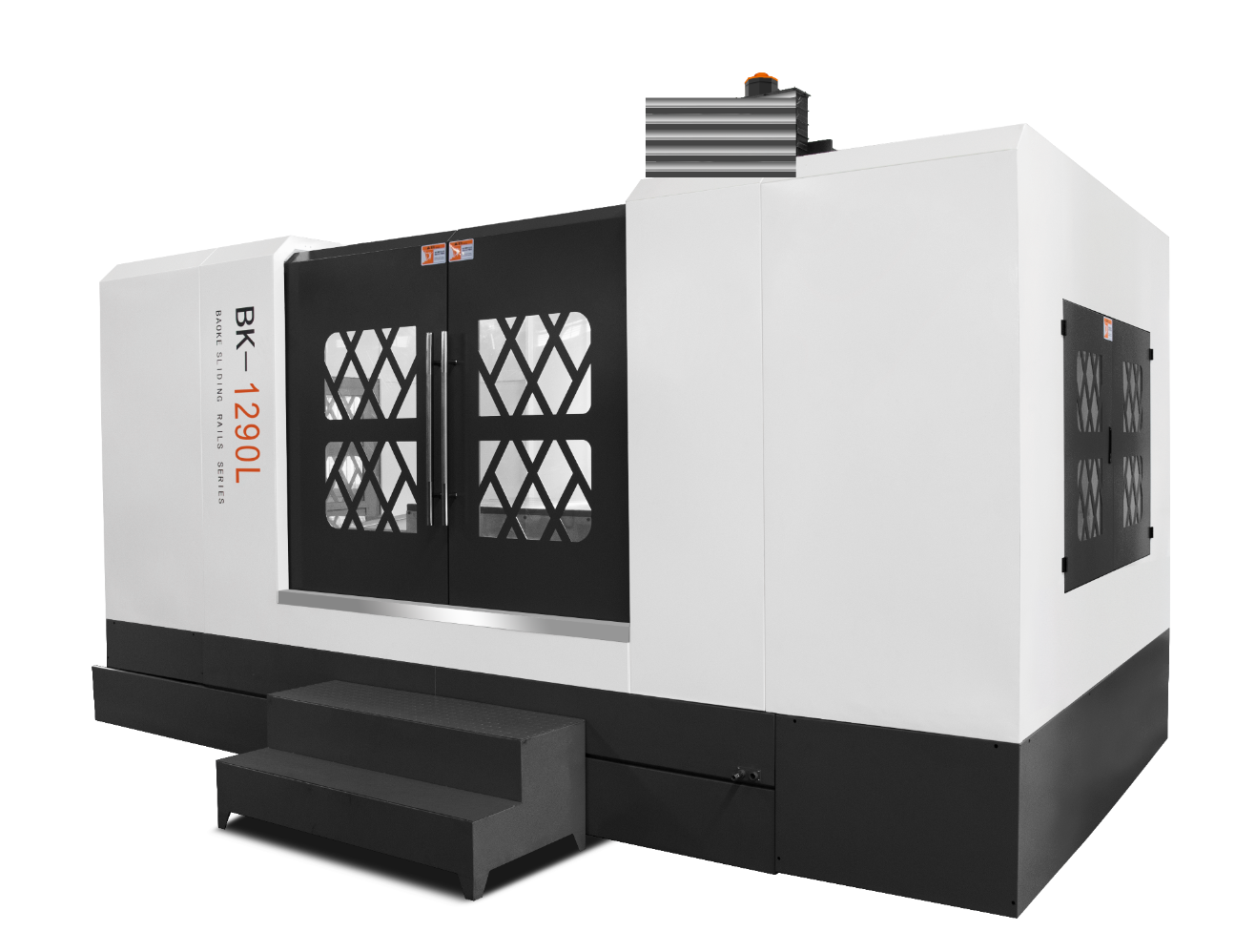

Vertical Machine Center BF-850V

BF-850V is a vertical machining center that provides high precision and high power with a very reasonable cost. This machine's features include an ultra-rigid structure, X/Y/Z axis high precision linear guide, ball screw with locking preload design, water cooling system, automatic lubrication system for the spindle shaft, etc. It can be widely used in the automotive, machinery, instrumentation and light industrial textile industries to fully demonstrate high precision and high efficiency machining capability at a very reasonable cost.

Technical Parameters

| Travel | X-axis travel | mm | 800 |

|---|---|---|---|

| Y-axis travel | mm | 500 | |

| Z-axis travel | mm | 500 | |

| Spindle nose to table | mm | 140-640 | |

| Spindle center to column | mm | 520 | |

| Table | Table Size (W×L) | mm | 900*500 |

| Table load | kg | 600 | |

| T-slot | No. | 5-18×100 | |

| Controller | Fanuc 0i-MF / Siemens 828D / Mitsubishi M80 | ||

| Spindle | Spindle Transmission | Direct drive | |

| Spindle speed | rpm | 12000 | |

| Spindle taper | BBT40 | ||

| Spindle motor | kw | 11/15 | |

| Spindle torque | Nm | 52.5/70/95.5(S1/S2 60min/S2 15min) | |

| X/Y/Z axis | X/Y/Z motor | kw | 3.0/3.0/3.0 |

| X/Y/Z motor torque | Nm | 20/45 | |

| X/Y/Z rapid feed rate | m/min | 30/30/30 | |

| Accuracy | Positioning accuracy | mm | 0.003/300 |

| Repeated positioning | mm | 0.002/300 | |

| Machine tool | Dimension | mm | 2600×2800×3030 |

| Weight | kg | 5500 | |

Detailed Photos

Product Description

BF-850V is designed with an ultra-rigid structure and X/Y/Z axis high precision linear guide and ball screw with locking preload design, which can provide you with fast, powerful, and stable machining performance, making it suitable for high precision parts machining and mold machining. It can be widely used in the automotive, machinery, instrumentation, light industrial textile, and electronic instrumentation industries, and can fully demonstrate high precision and high-efficiency machining capability at a very reasonable cost.

Machine design:

The machine tool is of C-type structure, mainly composed of table, column, saddle, base, spindle box, hydraulic system, lubrication system, cooling, and filtering system, electric control system, and other components.

Design highlights:

Super rigidity, stability, and deformation resistance

1) Adopt large span support, according to the principle of Bessel point physical deformation resistance, so that the casting to obtain the best deformation resistance structure. The body is designed by Finite Element Analysis(FEA) to ensure the stability and rigidity of the mechanism.

2) With the use of a double-layer box structure design, the weight will be 20% more than the single-layer structure, while the stability of the body, resistance to deformation, and rigidity will be much higher than the ordinary single-layer structure. The foot of the base is designed to be tilted outward to make the base more stable.

BBT40 spindle features:

Smaller vibration, stronger combination

1) Adopt BBT40 direct spindle, compared with ordinary BT 40 spindle, the tool swing is smaller at high speed, tool vibration is smaller, the tool pulling force is stronger, and the combination of tool shank and the spindle is more rigid. Adopting ceramic bearing, it has better precision, rigidity, and finish than a steel ball bearing.

2) The tapered surface and the end face of the BBT40 spindle can fit close to the tool holder at the same time, ensuring the required tool rigidity under heavy cutting conditions.

Fitted with a short nose spindle, the tooltip position is further in from the spindle fixing point for more stable spindle machining and greater rigidity.

The smaller the spindle vibration, the higher the surface processing quality, the more efficient tapping, and the longer tool life. The fastest tapping speed up to 6000 rpm, the smallest tooth can be tapped M1.0.

Mechanical Characteristics

1) Three axis 1G acceleration, rapid feed is 30m/min.

2) Three axis adopt high rigidity linear guideway, high speed, high precision.

3) Rear chip removal with the powerful chip flushing device, so there is no need to stop the machine to clean it.

4) Variable frequency tool magazine, angle sensing encoder, adjustable speed.

Standard Accessories

| Item | Brand |

|---|---|

| Spindle | Taiwan-Spintrue |

| Spindle bearing | Japan-NSK |

| Ball screw | Japan-NSK-C3 |

| Linear guideway | Germany-Rexroth |

| Pneumatic parts | Japan-Mitsubishi |

Optional Accessories

Controller | Mitsubishi | M80A |

|---|---|---|

| Siemens | 828D 3.14/3.14/3.14kw 9kw 12000SP | |

| 828D 3.14/3.14/3.14kw 18kw 15000SP water-cooled motor | ||

| 303/303/303B -- 11kw/15000 | ||

| Fanuc | 0i-MF(5) 3/3/3/15 biS22/3000*2+biS22B/3000+biI12 12000SP | |

| 0i-MF(3) 3/3/3/15 biS22/3000*2+biS22B/3000+aiI8/15000SP | ||

| 0i-MF(1) aiF22/3000*2+aiF22B/3000+aiI8/15000SP | ||

| Structure | Spindle | Spintrue BBT40-140-1500 direct drive |

| HSKA63-15000rpm Baofeng direct mechanical spindle | ||

| HSKA63-15000rpm Spintrue direct mechanical spindle | ||

| 7084/7084/7084 Simens 828D-271 system 3.14/3.14/3.14-15.5kw Germary Weiss-A63 electrical spindle | ||

| Spintrue direct (30kg coolant-through) biS22/3000*2+biS22B/3000+biIT12 10000SP | ||

| Spintrue direct (70kg coolant-through) biS22/3000*2+biS22B/3000+biIT12 10000SP |

Our Advantages

| Components | Baofeng | Others |

|---|---|---|

| Castings | HT300 | HT200/250 |

| Screw | Pre-stretching | / |

| Machine Design | Golden Ratio | / |

| Spindle VIbration | V1 | V4 |

| Oil Water Filter | Guideway | / |

| Joint Surface | Manually Scraping | Only Gasket / Grinder |

| Guideway Surface | Milling + Grinding | Only Milling |

| Metal Cover | 2.0/2.5mm | 1.8mm |

1) HT300 castings: Processing out of the iron crumbs are mostly in the form of strips, flakes, low dust ratio, processing surface color close to the steel.

2) Guide rail surface installation: Baofeng machine tool guide rail installation surface by high precision mother machine milling processing, and then by the imported guide rail grinding machine grinding processing, higher precision (peers basically only have milling processing).

3) Manually scraping: The rigidity and precision of our contact surfaces are higher than those of machines on the market that are ground by a grinding machine and not scraped by hand.

4) Assembly: Every step of the machine assembly is standardized, even the tightness of each screw has to meet the standard and be recorded.

5) Inspection standards: Baofeng adopts strict inspection standards to inspect the static and dynamic precision of the machine body and the whole machine.

6) Oil-water separation design: All of Baofeng's self-produced machines have oil-water separation design at the guide rail, which can extend the life of cutting fluid.

Works Show

After Sales Service

1) Baofeng promises to be responsible for all machines from Baofeng, regardless of where they are purchased from, regardless of their age, and can provide after-sales service for all machines confirmed as Baofeng.

2) All Baofeng machines are delivered with the company's after-sale number, and after-sale supervisor, design supervisor, and sales supervisor's mobile phone number to ensure that can be contacted us anytime.

3) Responsible for the quality of all Baofeng machines. Once the machine is found to have quality problems, we will do our best to solve them.

4) Provide 7*24 hours after-sales service and promise response in 4 hours. All machine tools maintenance only need to charge the cost of engineers travel. For all Baofeng machine tools, provide a free annual maintenance service.

About Us

FAQ

Q1. What's the MOQ?

A: 1 set.

Q2. What's your lead time?

A: It depends on the customer's requirement and quantity.

Q3. What's the payment term?

A: T/T or L/C. Negoiated.

Q4. How do you guarantee the quality of your products?

A: Each machine tests with professional Germany Inspection equipment before shipping.

Q5. Where is your factory located?

A: We have three factories in China. The biggest one is located in Huangshi City, Hubei Province; the other two are located in Dongguan City, Guangdong Province.