- NO63, XinTai Road, XinMaLian, DaLang Town, Dongguan City, Guangdong province

- info@baofengmachine.com

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

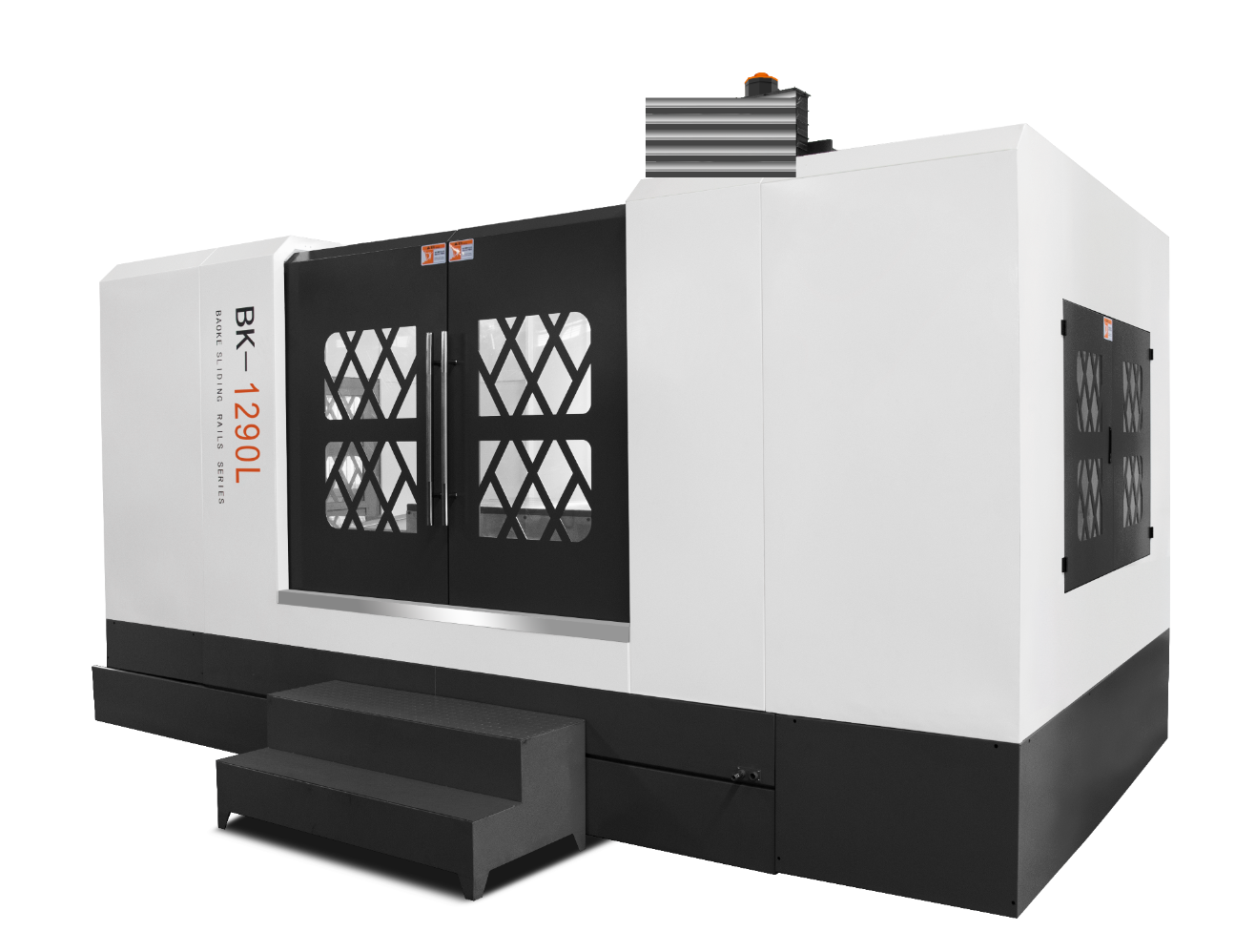

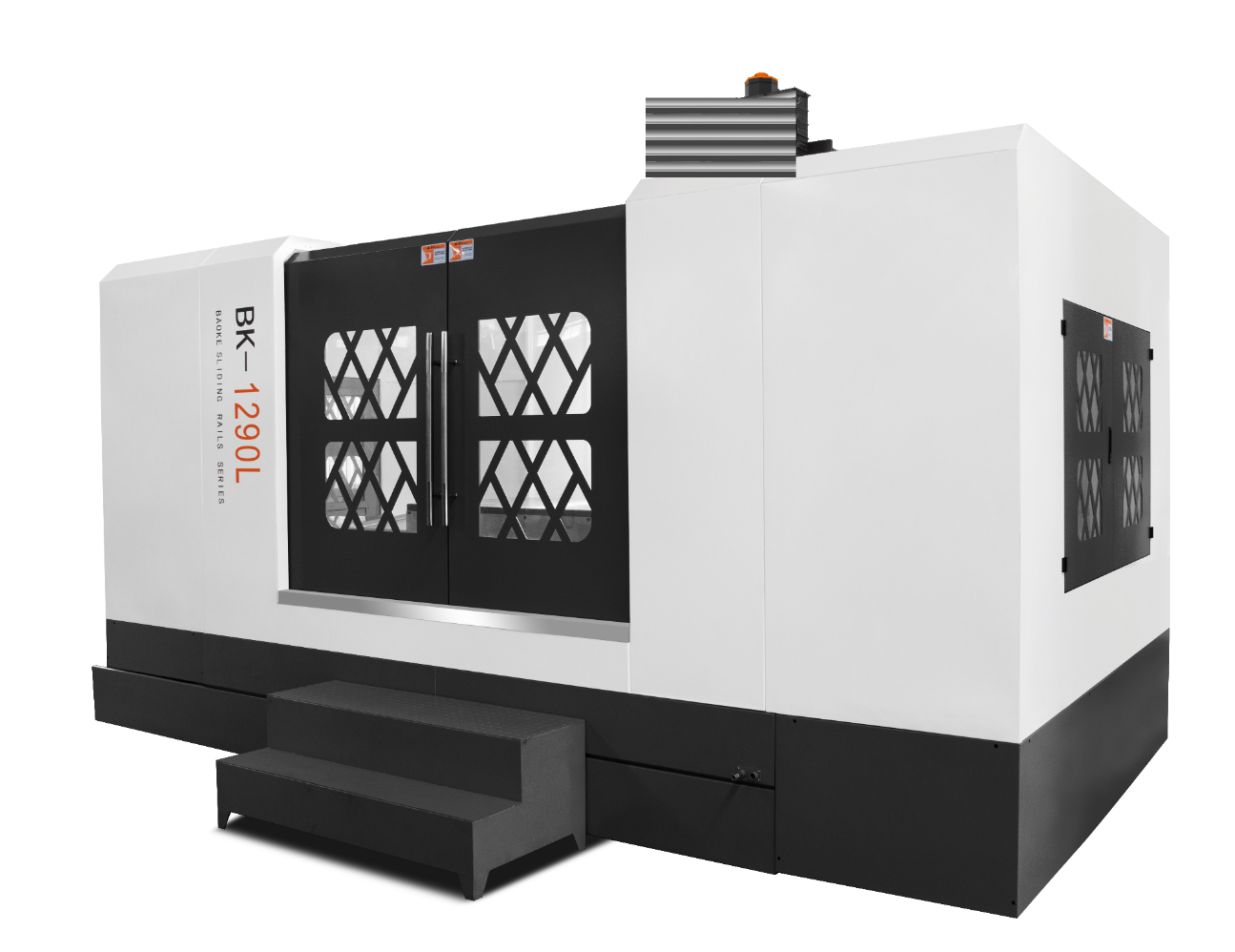

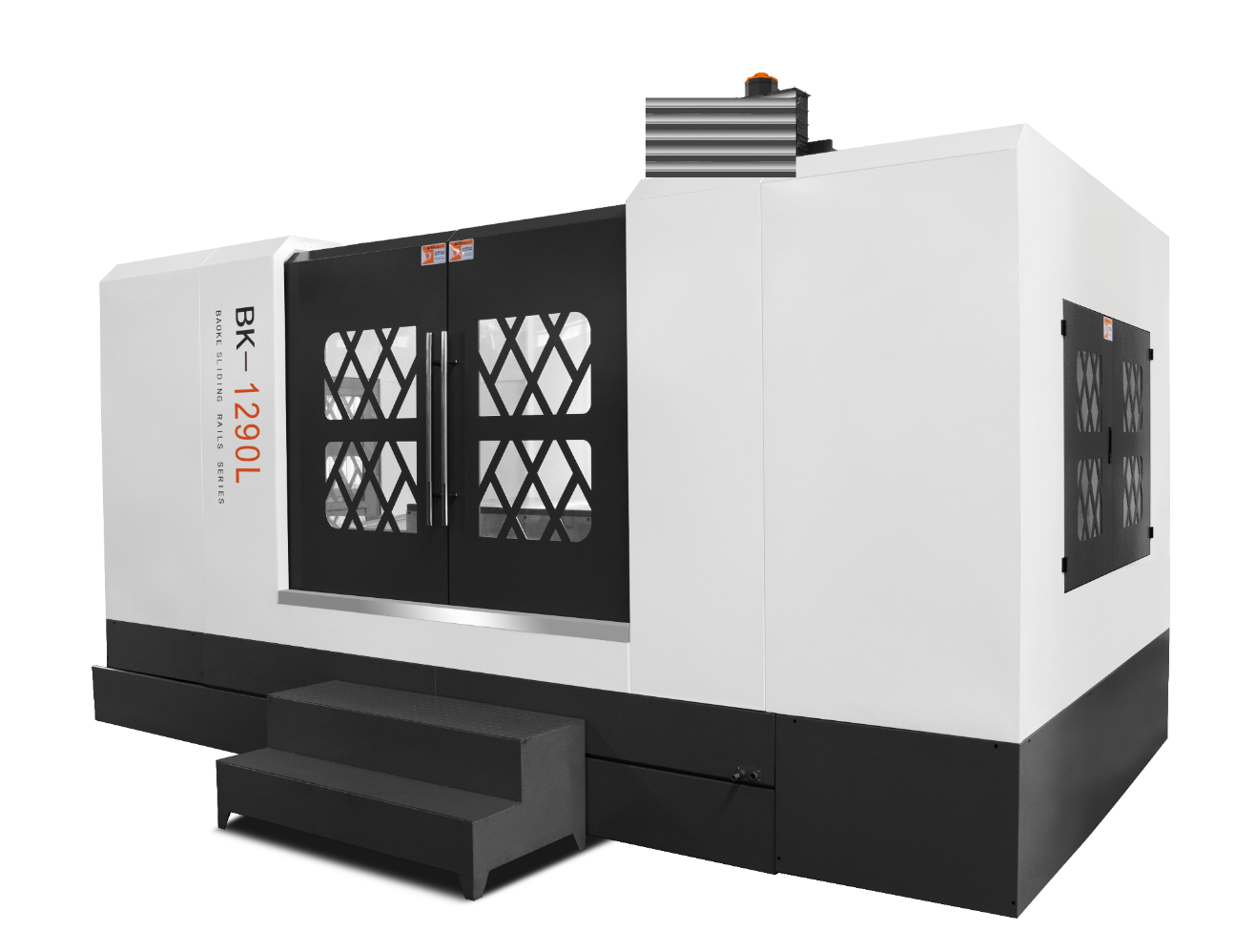

Horizontal Machine Center BK-1290L

The casting material of HT300 is mostly in the form of strips, flakes, low dust ratio and processing surface color close to steel. Our guide rails are more precise than those on the market ground by a milling machine and not scraped by hand. The construction process of every step is standardized, even for each screw. And we have strict inspection standards to inspect the static and dynamic precision of the machine body and whole machines

Technical Parameters

| Travel | X-axis travel | mm | 1200 |

|---|---|---|---|

| Y-axis travel | mm | 900 | |

| Z-axis travel | mm | 700 | |

| Spindle nose to table | mm | 70-970 | |

| Spindle center to column | mm | 0-700 | |

| Worktable | Table Size (W×L) | mm | 1360*700 |

| Table load | kg | 1000 | |

| Controller | Fanuc 0i-MF / Mitsubishi M80 | ||

| Spindle | Spindle Transmission | Belt drive+gear box | |

| Spindle speed | rpm | 8000 | |

| Spindle taper | BT50-45° | ||

| Spindle motor | kw | 18.5 | |

| X/Y/Z/B axis | X/Y/Z/B motor | kw | 4.5/4.5/4.5/4.5 |

| X/Y/Z/B motor torque | nm | 22/22/22/22 | |

| Accuracy | Positioning accuracy | mm | 0.005/300 |

| Repeated positioning | mm | 0.002/300 | |

| Machine tool | Dimension | mm | 3800*3200*3300 |

| Weight | kg | 10500 | |

Detailed Photos

Our Advantages

| Components | Baofeng | Others |

|---|---|---|

| Castings | HT300 | HT200/250 |

| Screw | Pre-stretching | / |

| Machine Design | Golden Ratio | / |

| Spindle VIbration | V1 | V4 |

| Oil Water Filter | Guideway | / |

| Joint Surface | Manually Scraping | Only Gasket / Grinder |

| Guideway Surface | Milling + Grinding | Only Milling |

| Metal Cover | 2.0/2.5mm | 1.8mm |

1. HT300 castings: Processing out of the iron crumbs are mostly in the form of strips, flakes, low dust ratio, processing surface color close to the steel.

2. Guide rail surface installation: Baofeng machine tool guide rail installation surface by high precision mother machine milling processing, and then by the imported guide rail grinding machine grinding processing, higher precision (peers basically only have milling processing).

3. Manually scraping: The rigidity and precision of our contact surfaces are higher than those of machines on the market that are ground by a grinding machine and not scraped by hand.

4. Assembly: Every step of the machine assembly is standardized, even the tightness of each screw has to meet the standard and be recorded.

5. Inspection standards: Baofeng adopts strict inspection standards to inspect the static and dynamic precision of the machine body and the whole machine.

6. Oil-water separation design: All of Baofeng's self-produced machines have an oil-water separation design at the guide rail, which can extend the life of cutting fluid.

Works Show

After Sales Service

1. Baofeng promises to be responsible for all machines from Baofeng, regardless of where they are purchased from, regardless of their age and can provide after-sales service for all machines confirmed as Baofeng.

2. All Baofeng machines are delivered with the company's after-sale number, and after-sale supervisor, design supervisor, and sales supervisor's mobile phone number to ensure that can be contacted us anytime.

3. Responsible for the quality of all Baofeng machines. Once the machine is found to have quality problems, we will do our best to solve them.

4. Provide 7*24 hours after-sales service and promise response in 4 hours. All machine tools maintenance only need to charge the cost of engineers travel. For all Baofeng machine tools, provide a free annual maintenance service.

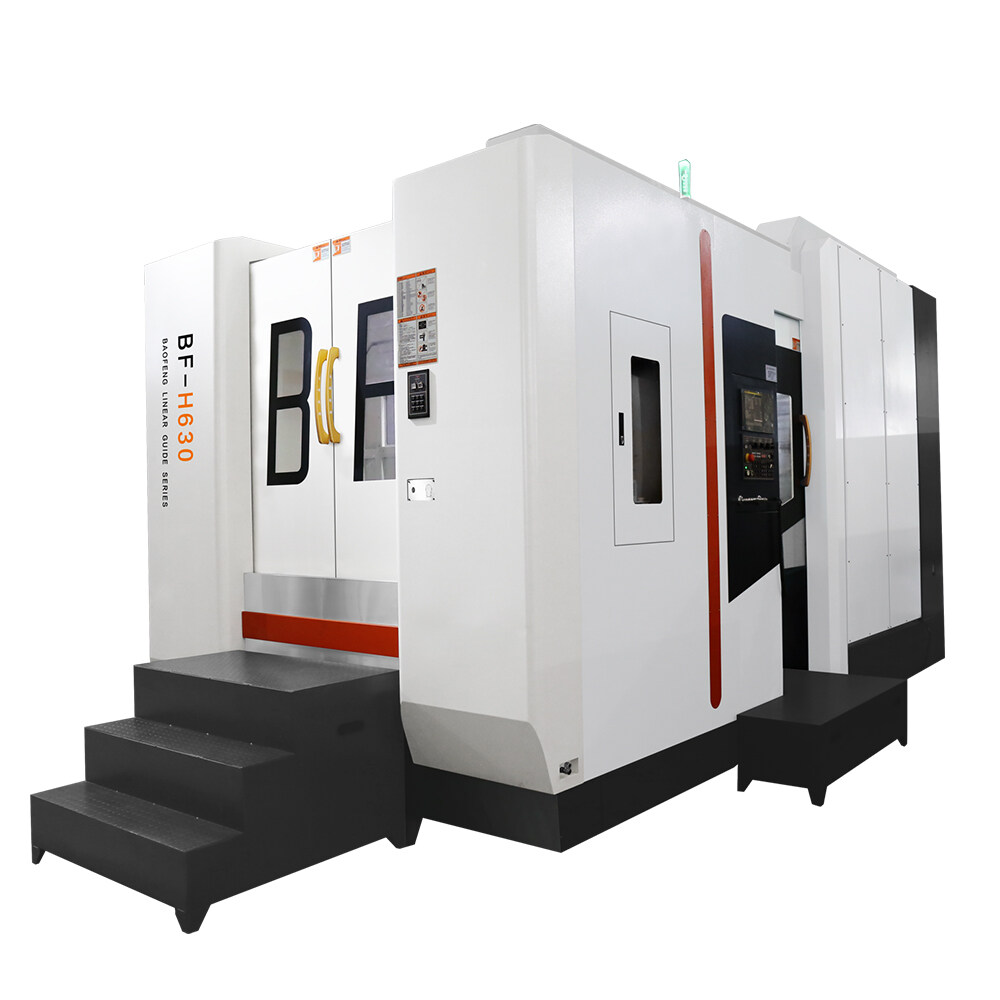

About Us

FAQ

Q1. What's the MOQ?

A: 1 set.

Q2. What's your lead time?

A: It depends on the customer's requirement and quantity.

Q3. What's the payment term?

A: T/T or L/C. Negoiated.

Q4. How do you guarantee the quality of your products?

A: Each machine tests with professional Germany Inspection equipment before shipping.

Q5. Where is your factory located?

A: We have three factories in China. The biggest one is located in Huangshi City, Hubei Province; the other two are located in Dongguan City, Guangdong Province.