- NO63, XinTai Road, XinMaLian, DaLang Town, Dongguan City, Guangdong province

- info@baofengmachine.com

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

BAOFENG BF-8032L Double Column Machining Center

Baofeng CNC Double Column Vertical Machining Centers combine proven machine design with advance technology in control and manufacturing. Reliability and performance make this series a favorite among demanding CNC work shops and in-house productions alike.

Description:

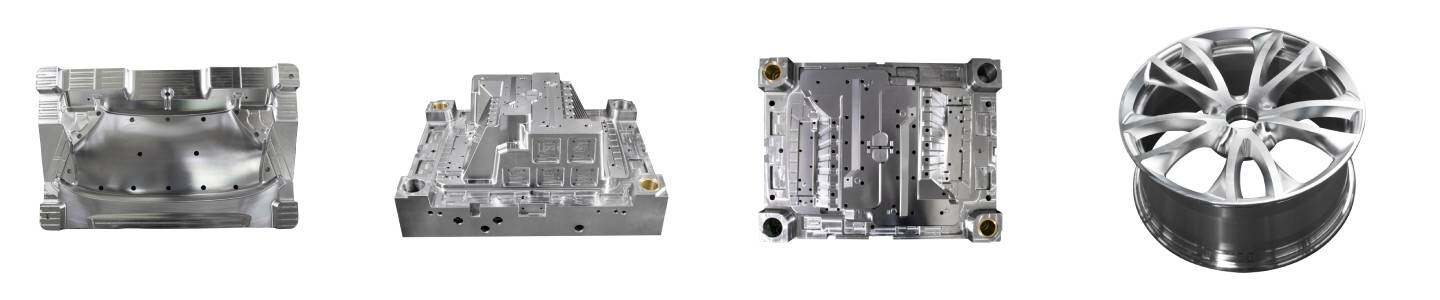

Double column machining center is mainly used for the processing of large boxes, complex surface molds, large-shaped parts,

and plate parts.

The Baofeng CNC Double Column Vertical Machining Centers combine proven machine design with advance technology in control and manufacturing.

Reliability and performance make this series a favorite among demanding CNC work shops and in-house productions alike.

Double Column VMCs come with large working capacity options of up to 8200*3600*1250mm travels and 8000*2600mm table area.

The heavy cutting spindle and rigid machine structure enable higher vertical machining efficiency with better finish and longer tool life – resulting in greater productivity and profitability all around.

Baofeng CNC Double Column VMCs are proven to increase productivity, delivering reliable and profitable performance.

For smaller size requirements, please see our Linear Way, Box Way, and Traveling Column vertical machining centers.

Special model

- Equipped with Germany ZF Gearbox or Taiwan gear type spindle box to realize strong cutting.

- Equipped with Taiwan right angle milling head to realize simple horizontal machining requirements.

- Equipped with Taiwan universal milling head to realize multiple angle machining requirements.

- Equipped with automatic pentahedron milling head to realize multiple dimension high precision machining.

Specification

| Travel | X-axis | mm | 8200 |

|---|---|---|---|

| Y-axis | mm | 3600 | |

| Z-axis | mm | 1250 | |

| Spindle nose to table | mm | 350-1600 | |

| Width of gantry | mm | 3200 | |

| Worktable | Table size | mm | 8000 x2600 |

| Maximum load on table | kg | 35000 | |

| T-slot | 13-26x200 | ||

| Controller | Fanuc System | 0I-MF | |

| Spindle | Driving type | belt drive spindle | |

| Spindle speed | rpm | 6000 | |

| Spindle taper and specifications | BT50 | ||

| Spindle motor power | kw | 22/26KW8000 rpm | |

| 3 axis motor | X/Y/ Z axis motor power | kw | 9.0/7.0/7.0 |

| X/Y/Z rapid feed | m/min | 12/12/12 | |

| Machine accuracy(X/Y/Z) | Positioning accuracy | mm | 0.005/300 |

| Repeat positioning accuracy | mm | 0.003/300 | |

| Machine | Dimension | mm | 18000x7000x6000 |

| Weight | Kg | 82000 |

Optional configuration:

- SIEMENS/FANUC/Mitsubishi CNC Controller

- 24T/30T Arm type tool magazine

- Coolant through spindle

- 4th/5th-axis rotary table

- Chip conveyor

- Tool setter

- Oil mist collector

FAQ

Q1. What's the MOQ?

A: 1 set.

Q2. What's your lead time?

A: It depends on the customer's requirement and quantity.

Q3. What's the payment term?

A: T/T or L/C. Negoiated.

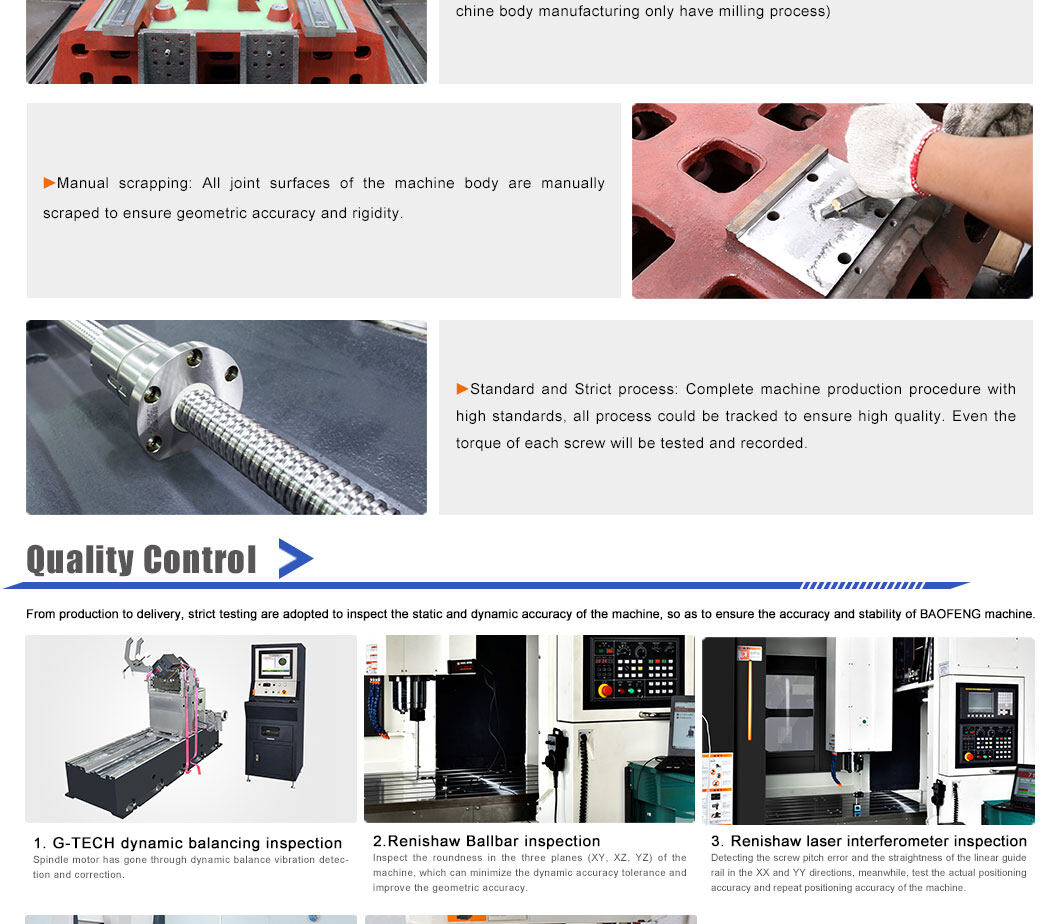

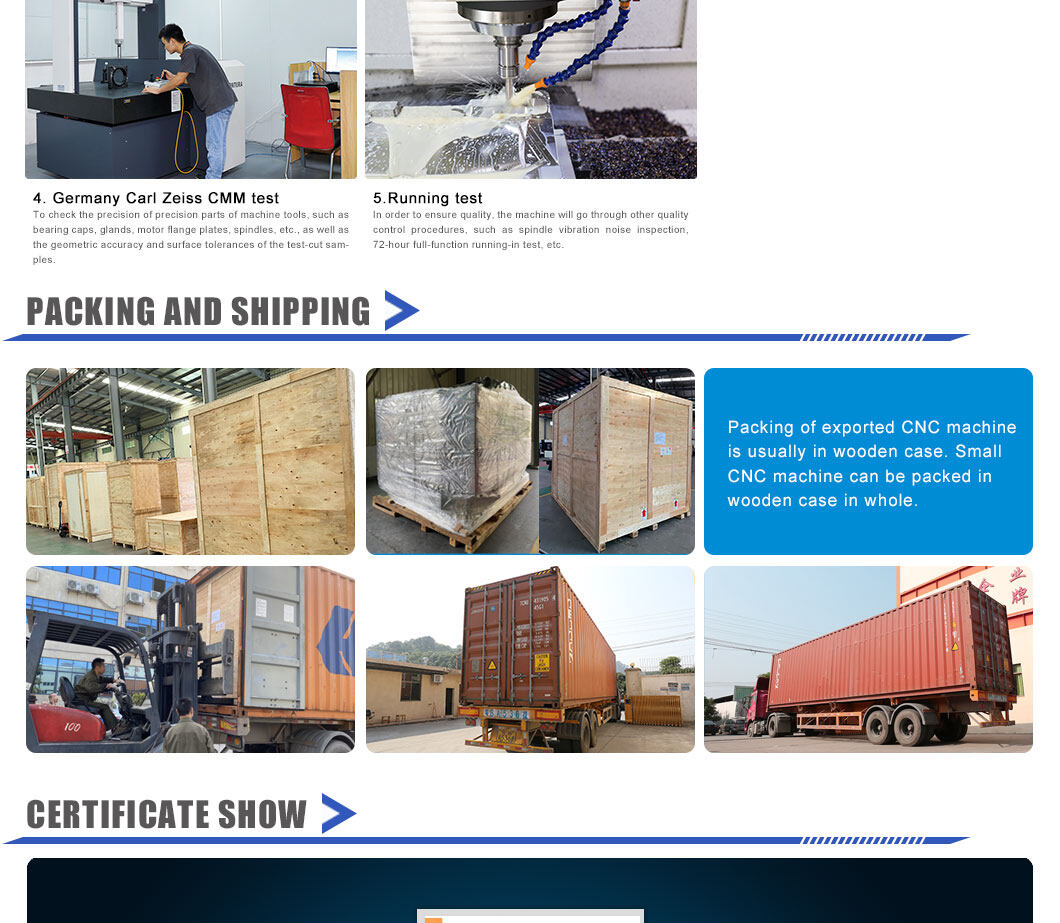

Q4. How do you guarantee the quality of your products?

A: Each machine tests with professional Germany Inspection equipment before shipping.

Q5. Where is your factory located?

A: We have three factories in China. The biggest one is located in Huangshi City, Hubei Province;

the other two are located in Dongguan City, Guangdong Province.