- NO63, XinTai Road, XinMaLian, DaLang Town, Dongguan City, Guangdong province

- info@baofengmachine.com

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

China Cnc Machine Manufacturer

China Top CNC Milling Supplier & Manufacturer – BAOFENG offers worldwide clients affordable, rapid, high-precision custom CNC Milling center, a variety of materials available to meet the needs of different industries!

CNC machines are used in various industries for precise and efficient machining of complex parts. Both horizontal and vertical CNC machines offer advantages in terms of productivity, accuracy, and flexibility. Horizontal CNC machines are often used for heavy-duty machining and for producing large, complex parts that require multiple machining operations. In contrast, vertical CNC machines are better suited for small to medium-sized parts that require high accuracy and precision.

The choice between a horizontal and vertical CNC machine depends on various factors such as the size and complexity of the workpiece, the type of machining operation required, the production volume, and the available floor space. CNC machines can be programmed to perform multiple operations automatically, making them a popular choice for high-volume production runs.

horizontal and vertical CNC machine

In a horizontal machine, the spindle is placed horizontally, parallel to the ground, and the workpiece is mounted on a table that moves in and out and side to side. The cutting tool is typically mounted on a horizontal arbor and moves across the workpiece in a perpendicular direction. This type of machine is often used for milling, boring, and drilling operations.

In a vertical machine, the spindle is placed vertically, perpendicular to the ground, and the workpiece is mounted on a table that moves up and down and side to side. The cutting tool is typically mounted on a vertical arbor and moves up and down to cut into the workpiece. This type of machine is often used for drilling, tapping, and other operations where a high degree of accuracy is required.

Both types of machines have their advantages and disadvantages, and the choice between them depends on the specific application and the type of workpiece being machined.

BaoFeng Offers Various Types Of The Vertical Machining Center, Cnc Vertical Machining Center , Linear Guide Machining Center , Cnc Horizontal Machining Center, Gantry Type Machining Center, Cnc 5 Axis Machining Center, Vmc Vertical Machining Center, Double Column Machining Center For Customers.and Baofeng Has 12 Years Of Cnc Machine Tool Manufacturing Experience, Providing Customers Worldwide. High-quality Chinese Brand Cnc Machine Tools.

CNC engraving machine

(3)BAOFENG 650E engraving and milling machine center

X/Y/Z Axis are linear guide way, 3 axis standard rapid feed 8 m/min. High rigidity machine body ensures cutting requirements can be met. BF-650E has high precision, high rigidity machine body maintains the processing stability during high rotation speed. Special reinforced spindle case design, the cutting strength increased 20% in comparison with similar models

BAOFENG BF-870E Linear Machining Center

X/Y/Z Axis are linear guide way, 3 axis standard rapid feed 12 m/min.High rigidity machine body ensures cutting requirements can be met. High precision, high rigidity machine body maintains the processing stability during high rotation speed. Special reinforced spindle case design, the cutting strength increased 20% in comparison with similar models .

BAOFENG BF-650E Graphite Engraving Machining Center

X/Y/Z axis are linear guide way, 3 axis standard rapid feed 12 m/min. High precision, high rigidity machine body maintains the processing stability during high rotation speed. Special reinforced spindle case design, the cutting strength increased 20% in comparison with similar models . Coupling, spindle bearing, spindle, ball screw, and other key parts are imported from Germany, Japan and Taiwan top brands to ensure high quality and stability.

CNC tapping center

(4)BAOFENG T800 drilling and tapping center

BF-T800 Vertical tapping machine is featured for high speed rotation, fast and high precision small hole machining and fast tool changing. It could be applied in the processing of small-plate parts, disc-shaped parts and shells, which is widely used in 3C, automotive, watches, electronics, small mold and medical treatment equipment

BAOFENG T10 drilling and tapping center

Our High speed drilling and tapping machine center is featured for high speed rotation and fast and high precision small hole machining. It could be applied in the processing of small-plate parts, disc-shaped parts and shells, which is widely used in 3C, automotive, watches, electronics, small mold and other industries.

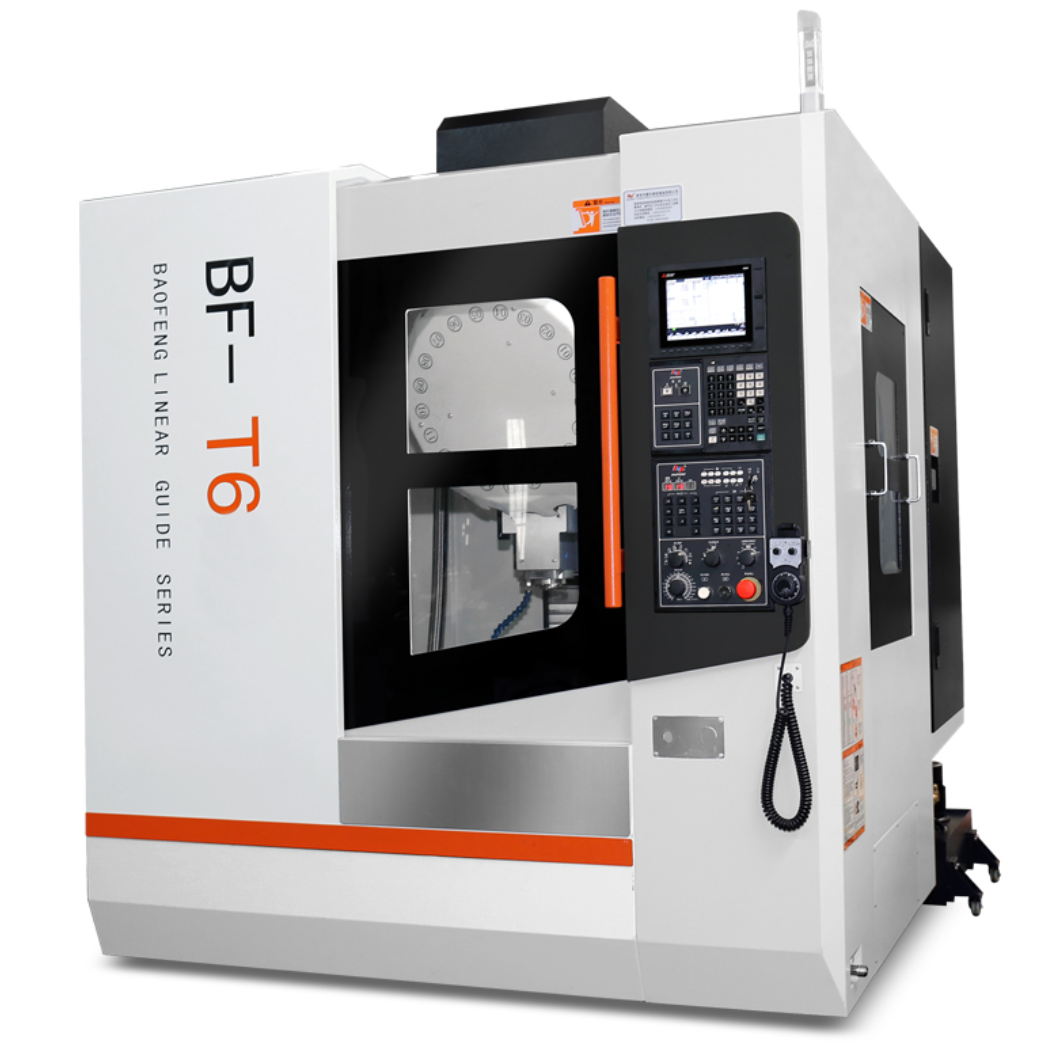

BAOFENG T6 drilling and tapping center

The BF-T6 is a high speed mini gearbox with high precision. It can rotate at high speed and can machine small holes with high precision. This gearbox is widely used in the 3C, automotive, watch, electronics, small moulds and medical device industries.

BAOFENG T600 drilling and tapping center

The new X/G5 is an upgraded version of our X/G3 3-axis CNC Router. It is equipped with a LCD screen and wireless remote controller for easy access to all the functions. The superior X/Y tube stable and precise motion control, combined with high accuracy spindle make it more suitable for complex machining applications like PCB prototyping, vases, bottle stoppers etc.