- NO63, XinTai Road, XinMaLian, DaLang Town, Dongguan City, Guangdong province

- info@baofengmachine.com

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

News

How to Maintain a Vertical Machining Center

As we all know, proper maintenance is of great significance to the service life and accuracy of equipment. The vertical machining center is a composite machining equipment integrating oil, gas and electricity, so it needs to be maintained more carefully. How to maintain the machining center if it is not used for a long time?

How to maintain a vertical machining center?

1️⃣It is necessary to clean up the whole machine, including the worktable, body, spindle cooling and machining debris on the transmission system of the tool magazine, and take out the tool holder in the tool magazine for anti-rust treatment, and with a special knife handle storage box separately packaging.

2️⃣Anti-rust maintenance is essential. Anti-rust liquid should be applied to the table surface, spindle screw and other parts of the machining center to avoid rust affecting its accuracy. In addition, the telescopic shield of the vertical machining center should also be coated with anti-rust liquid.

The vicinity of the Y-axis motor at the bottom of the column is particularly prone to contamination with oil and debris, which needs to be carefully cleaned. If the downtime of the machining center is long, it is necessary to open the X and Y axis shields with a hexagonal wrench, and then apply anti-rust liquid to the screw.

3️⃣The downtime of the machining center is too long, and the three axes need to run to the middle position of each axis to turn off the equipment, so that it is in a state of stress balance; it is necessary to avoid staying at the limit position of the moving axis, so that the uneven force will affect the accuracy of the equipment.

4️⃣If the processing environment is relatively humid, you'd better block the control box filter and the fan sticker of the electric box to avoid the malfunction of electrical components due to damp weather.

5️⃣The production workshop should prevent rodents from damaging the machine lines and causing processing failures. When the equipment is not suitable for a long time, check the power supply voltage of the machine tool when it is turned on again. The power switch of the machine tool can only be turned on after the voltage stabilizes for about 10 minutes after the main power switch is turned on. Then turn on the other power switches in the electric box in turn. At the same time, it cannot be processed immediately. It is necessary to perform idling preheating of the spindle. Turn on the spindle to preheat for half an hour before normal processing. At the same time, check the oil level of the hydraulic system, the level of the tool coolant, and check whether there is water or oil in the compressed air filter. .

In conclusion

If any equipment wants to maintain long-term stable machining accuracy, it is inseparable from the maintenance and protection of scientific systems. If the vertical machining center is not suitable for a long time, the protection work of rust prevention and power switch must be put in place, so as not to affect the accuracy of the equipment when it is restarted for processing, and maintain high-precision and efficient processing.

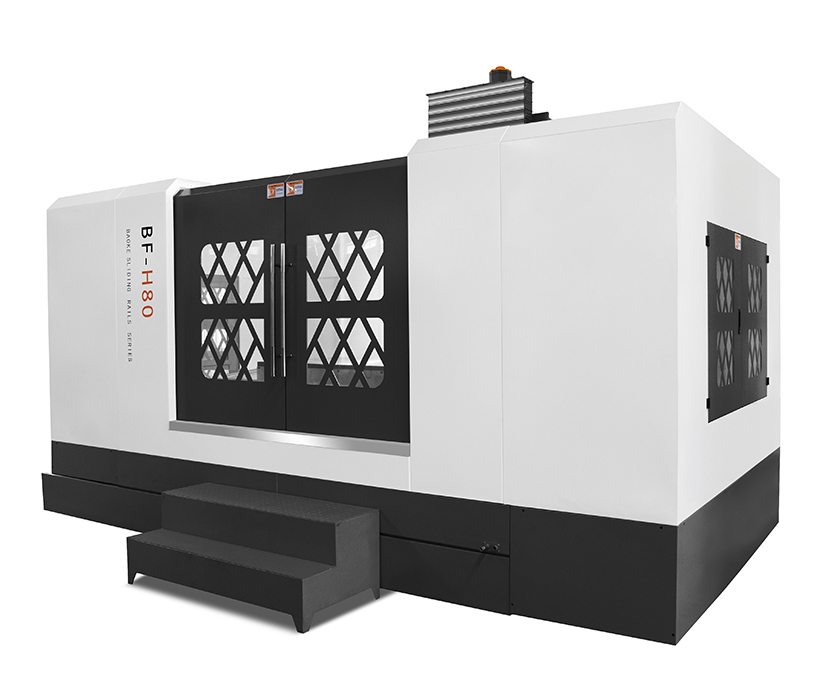

Due to the complexity and precision of CNC machining, a small mistake can lead to the complete scrapping of the workpiece, causing serious damage to the life of the equipment. We are professional and leading CNC machining center manufacturer, providing customers with premium vmc 1000 cnc, vmc 3 axis and vmc2100b, for more information, such as vmc2100b price, please feel free to contact us, we will give you the best price.