- NO63, XinTai Road, XinMaLian, DaLang Town, Dongguan City, Guangdong province

- info@baofengmachine.com

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

News

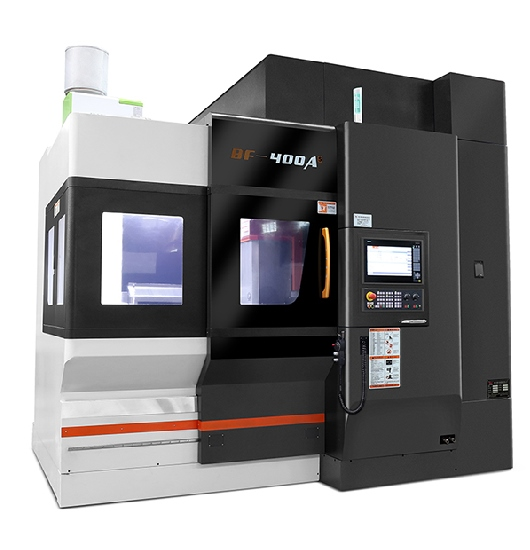

Brief Introduction of Vmc 600

As a professional vmc 3 axis machine manufacturer, we'd like to talk with you today about our company's product - vmc 600.

Instructions for vmc 600

Firstly, this series of machine tools are suitable for the military industry, aerospace, automobile, mold, instrument, and other machining industries to process all kinds of parts with high precision, many processes, and complex shapes.

VMC series vertical machining center adopts an electromechanical hydraulic integration structure, with a compact and reasonable overall layout, a small floor area, and convenient installation and maintenance.

The worktable of this series of machine tools carries out cross slide movement. The single-column structure is equipped with a high-speed spindle, strong tool cooling, and chip removal functions, providing a clean working space.

This series of machine tools adopt a closed protective structure to improve production safety and reduce pollution to the production and operation environment. The key purchased parts of this series of machine tools adopt imported components so that the whole machine has high reliability and high durability.

VMC series vertical machining centers are mainly used in military industry, aerospace, automobile, mold, instrument, and other mechanical processing industries to process various parts with high precision, many processes, and complex shapes. It can be used for medium and small batch and multi-variety production, and can also enter the automatic production line.

Equipment characteristics

VMC series CNC milling machines and vertical machining centers have the advantages of high speed, high precision, and high stability.

The machine tool has a high degree of mechanical and electrical integration, a simple and beautiful appearance, and is easy to operate.

The equipment is mainly used for the processing of molds, aluminum boxes, and other parts. Parts processing has strong adaptability and good flexibility and can process parts with particularly complex contour shapes or difficult to control the size, such as mold parts, shell parts, complex curve parts, and three-dimensional space surface parts.

- The fuselage, base, and workbench saddle are designed inbox structure and cast by high-grade cast iron, which is stress relieved. Maintain the accuracy and stability of the machine tool. The rigid span of the guide rail is larger than that of similar products.

- The spindle adopts the high-precision and high-speed spindle unit produced by European technology, which can ensure the long service life and long-term stability of precision of the machine tool.

- The important supporting parts of the machine tool, such as spindle bearing, RAM guide rail, ball screw, electrical components, etc., are from famous foreign manufacturers. The electrical assembly is carried out under constant temperature and the inspection is strict. The machine tool ensures the ex-factory quality of the products through multi-layer inspection such as imported three-dimensional measurement, British Renishaw laser interferometer, British Renishaw Club instrument, imported projector, electrical optimization test software of Mitsubishi and German Siemens.

Of course, our company also supply vmc 800 and other high-quality products. We are the leading and professional vmc 3 axis machine supplier, any interests, plz feel free to contact us.