- NO63, XinTai Road, XinMaLian, DaLang Town, Dongguan City, Guangdong province

- info@baofengmachine.com

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Please enter the email address you’d like your password reset information sent to.

Email format error

Email cannot be empty

Email does not exist

Reset account password

For the account

6-20 characters(letters plus numbers only)

The password is inconsistent

Reset success

Your password was reset. You can log in using your new password.

Login

News

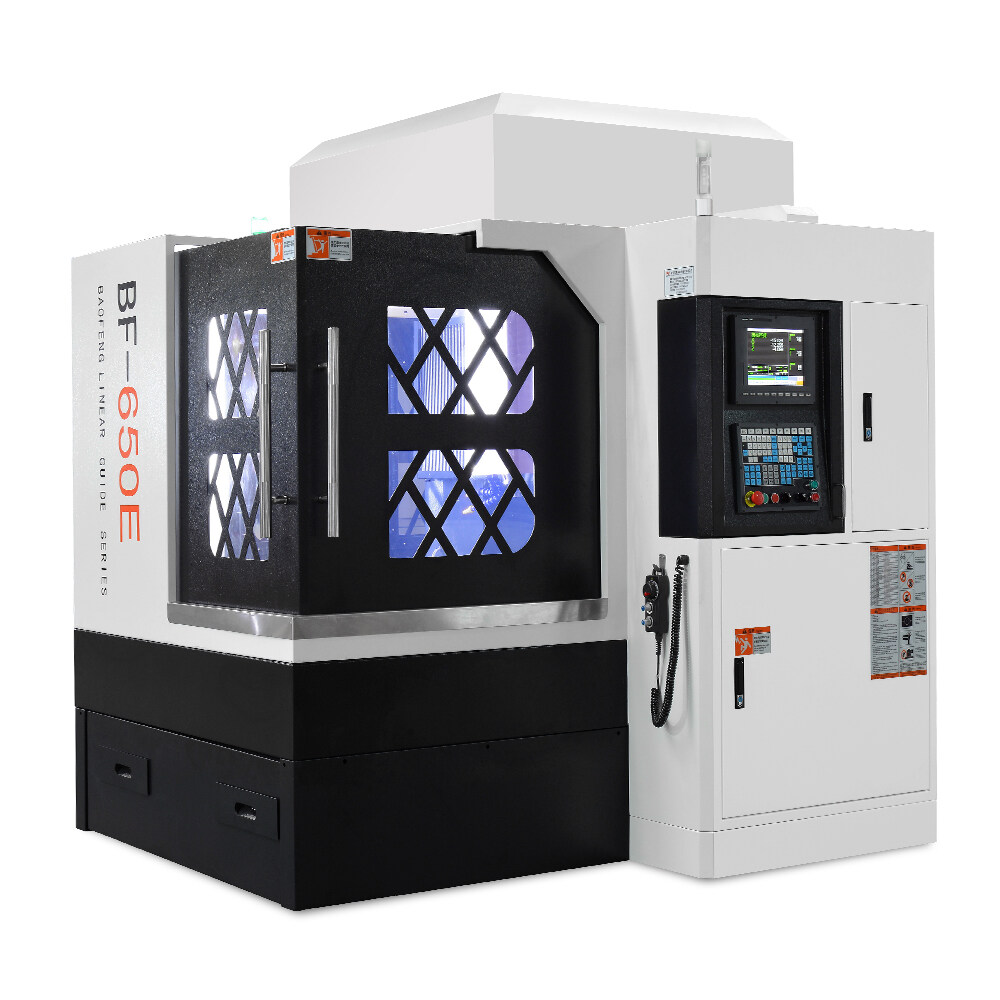

Unveiling the Power of Engraving and Milling Machine Centers

2025-03-03 11:00:09

In the world of modern manufacturing, precision and versatility are the keys to success. Whether you're crafting intricate jewelry, designing complex molds, or producing high-tech components, the right machinery can make all the difference. Today, we're diving deep into a fascinating piece of equipment that has revolutionized the way we approach precision manufacturing: the Engraving and Milling Machine Center. If you're curious about how this technology works and why it's so important, you've come to the right place.

What is an Engraving and Milling Machine Center?

Imagine a machine that can carve intricate designs into wood, etch detailed patterns into metal, and mill complex shapes with pinpoint accuracy—all in one compact unit. That's the essence of an Engraving and Milling Machine Center. This versatile piece of equipment combines the precision of an engraving machine with the robust capabilities of a milling machine, making it a powerhouse for a wide range of applications.

At its core, an Engraving and Milling Machine Center is a type of CNC (Computer Numerical Control) machine. This means it uses computer software and numerical control systems to guide its movements, ensuring that every cut, carve, and mill is executed with incredible precision. Whether you're working with metals, plastics, wood, or even stone, this machine can handle it all.

Key Features and Capabilities

Precision at Its Finest

One of the standout features of an Engraving and Milling Machine Center is its ability to achieve incredibly high levels of precision. These machines can work within tolerances as tight as 0.005 to 0.05 millimeters. To put that into perspective, that's finer than a human hair! This level of precision is crucial for applications like mold making, where even the slightest deviation can affect the final product's quality.

Versatility in Materials

Another remarkable aspect of these machines is their ability to work with a wide range of materials. Whether you're crafting delicate jewelry out of gold or silver, carving intricate designs into hardwood, or milling complex components out of aluminum, an Engraving and Milling Machine Center can handle it all. This versatility makes it an invaluable tool for manufacturers across various industries.

Advanced Technology

Modern Engraving and Milling Machine Centers come equipped with advanced features that enhance their capabilities. For instance, many models include high-precision optical linear scales that can achieve accuracy within ±5 micrometers. Some even come with automatic tool changers (ATC) and state-of-the-art CNC systems like Siemens 828D, which significantly boost productivity and efficiency.

Applications Across Industries

Mold Making

In the world of mold making, precision is everything. Engraving and Milling Machine Centers are perfect for crafting small and complex molds, such as those used in plastic injection molding or die casting. They can create intricate 3D molds, copper electrodes, and even shoe molds with ease. This makes them a favorite among manufacturers who need to produce high-quality molds quickly and efficiently.

Craftsmanship and Artistry

For artisans and craftsmen, these machines are a dream come true. Whether you're a woodworker creating intricate carvings, a jeweler designing delicate pieces, or a sculptor working with stone, an Engraving and Milling Machine Center can help bring your vision to life. They can carve detailed patterns, etch designs, and create complex shapes with a level of precision that would be nearly impossible to achieve by hand.

Electronics and Beyond

The electronics industry also benefits greatly from Engraving and Milling Machine Centers. These machines are perfect for producing small, high-precision components like electronic device casings, buttons, and connectors. Their ability to work with materials like aluminum and plastic makes them ideal for creating the sleek, modern designs we've come to expect from our gadgets.

Why Choose an Engraving and Milling Machine Center?

If you're in the market for a new piece of manufacturing equipment, an Engraving and Milling Machine Center offers several compelling advantages. First and foremost, it combines the capabilities of multiple machines into one, saving you space and money. Instead of investing in separate engraving and milling machines, you can have both functions in one compact unit.

Secondly, the precision and versatility of these machines make them suitable for a wide range of applications. Whether you're a small-scale artisan or a large manufacturing operation, there's a model that fits your needs. And with advanced features like automatic tool changers and high-precision scales, you can achieve incredible results with minimal effort.

Personal Experience: A Game-Changer in Action

A few years ago, I had the opportunity to work with a company that specialized in custom jewelry making. They had recently invested in an Engraving and Milling Machine Center, and the difference it made was astounding. Before the machine, creating intricate designs required hours of meticulous handwork. With the new machine, they could produce the same designs in a fraction of the time, with even greater precision.

One particular project stands out in my mind. They were working on a custom ring with an intricate floral design. The level of detail required would have taken days to complete by hand. Using the Engraving and Milling Machine Center, they were able to carve the design into the metal in just a few hours. The result was a stunning piece of jewelry that looked like it had been crafted by a master artisan. This experience truly showcased the power of these machines to transform the way we approach manufacturing.

Conclusion:

As technology continues to advance, Engraving and Milling Machine Centers are becoming more powerful and accessible than ever. They offer a unique blend of precision, versatility, and efficiency that makes them indispensable in today's manufacturing landscape. Whether you're a small business looking to expand your capabilities or a large operation seeking to streamline your processes, these machines are worth considering.

Engraving and milling machine centers are important. They offer precision and speed. Manufacturers can create intricate designs. They can also make complex components easily. You might want to explore these machines. They can take your manufacturing to the next level.

Prev Post

Next Post

Contact us