- NO63, XinTai Road, XinMaLian, DaLang Town, Dongguan City, Guangdong province

- info@baofengmachine.com

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

News

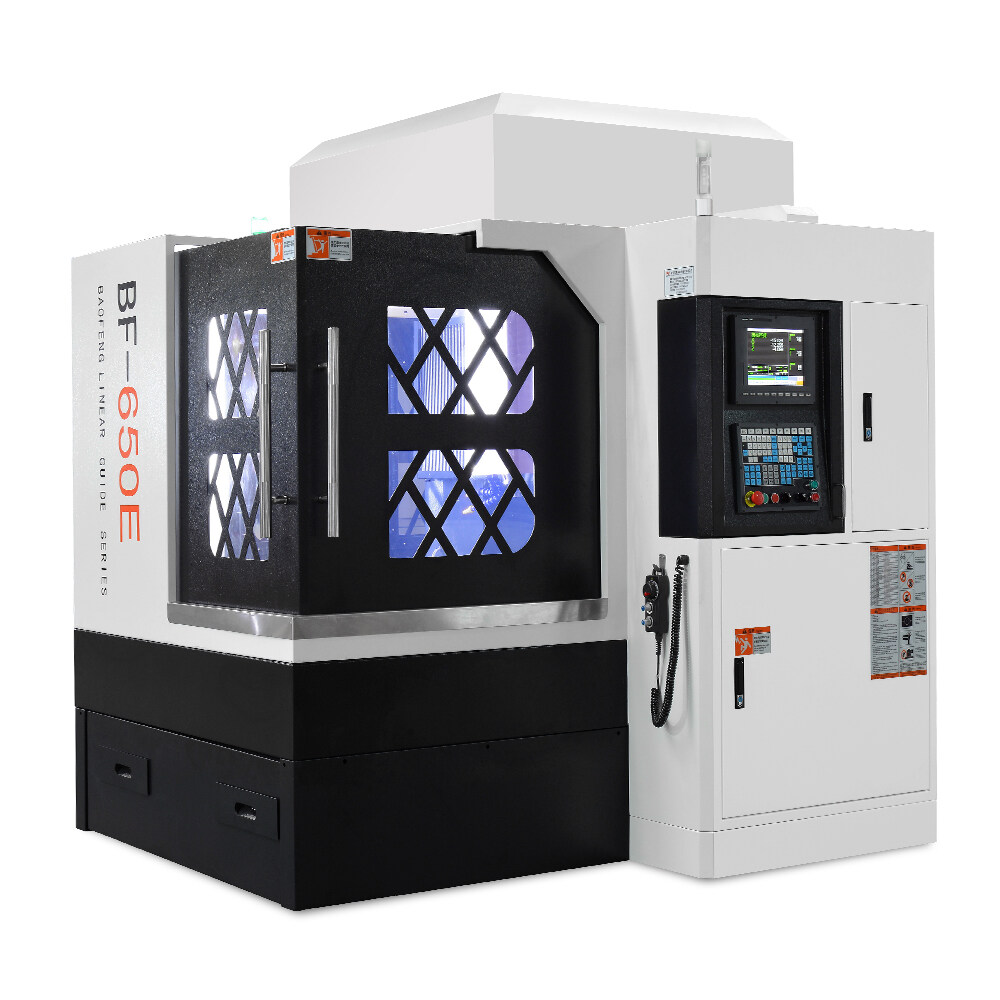

Some Information of the CNC Engraving Machine

As a kind of mechanical equipment that can process and engrave a variety of materials, the engraving machine also has a wide range of applications in the production process of various industries.

With the use of CNC numerical control technology combined with frequency conversion controller and servo drive equipment, today's CNC milling engraving machine has gradually become the mainstream configuration in the engraving industry. Next, in this blog, I will give a full overview of the product.

The Composition of the CNC Engraving Machine

CNC engraving machine is mainly composed of CNC numerical control system, spindle positioning system, and spindle rotation system. The functions of each part are as follows:

- CNC numerical control system

Design and layout are carried out through the special engraving software configured in the CNC engraving machine, and the information of design and layout is transmitted to the engraving machine controller through the computer.

Next, the controller converts this information into pulse signals that can drive the stepping motor or servo motor, and the positioning system completes the design and layout pattern model by receiving the pulse signal to complete the positioning.

- Servo positioning system

Three-axis positioning can be accomplished by using three axes that are perpendicular to each other in three-dimensional space. Therefore, the three sets of servo positioning systems respectively accept the pulse signals from the CNC numerical control system to complete the arbitrary pattern model in the three-dimensional space.

- Spindle machining system

The servo positioning system completes the setting of the pattern model, and the corresponding engraving work needs to be completed at the corresponding fixed position to complete the engraving items typed by the CNC engraving machine system.

The Advantages of CNC Engraving Machine

✔️ Low business expenses

Investing in a CNC granite engraving machine can help reduce operating costs, provide better material yield, and prevent wasting expensive materials.

✔️ Short delivery time

CNC engraving machine enables faster cutting cycle times and accurate information. Customers will know exactly how many minutes it takes to run a job on the CNC, which will allow them to better plan and calculate operational costs.

✔️ Good edge handling

The CNC granite engraving machine will accurately follow the geometry of the programmed part.

✔️ Better material yield

All CNC parts can be nested together to maximize material utilization. This reduces the amount of material used, which reduces overhead costs.

✔️ More accurate operation

CNC granite engraving machine is very repeatable. This precision ensures that both the geometry of the part and the cut of the product are perfect.

✔️ Greater flexibility

The only limit is the user's imagination. This new ability to create anything opens up new opportunities for businesses to produce products that cannot be produced manually.

✔️ Faster cycle times

CNC engraving machines move faster and more accurately. This reduces or eliminates secondary manual finishing. Faster cycle times generate greater profits.

Conclusion

I believe that through the introduction of the above information, you have a better understanding of the CNC engraving machine. If you want to gain more industry-related knowledge, you can follow our official website. If you are interested in our products, please contact us.