- NO63, XinTai Road, XinMaLian, DaLang Town, Dongguan City, Guangdong province

- info@baofengmachine.com

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

News

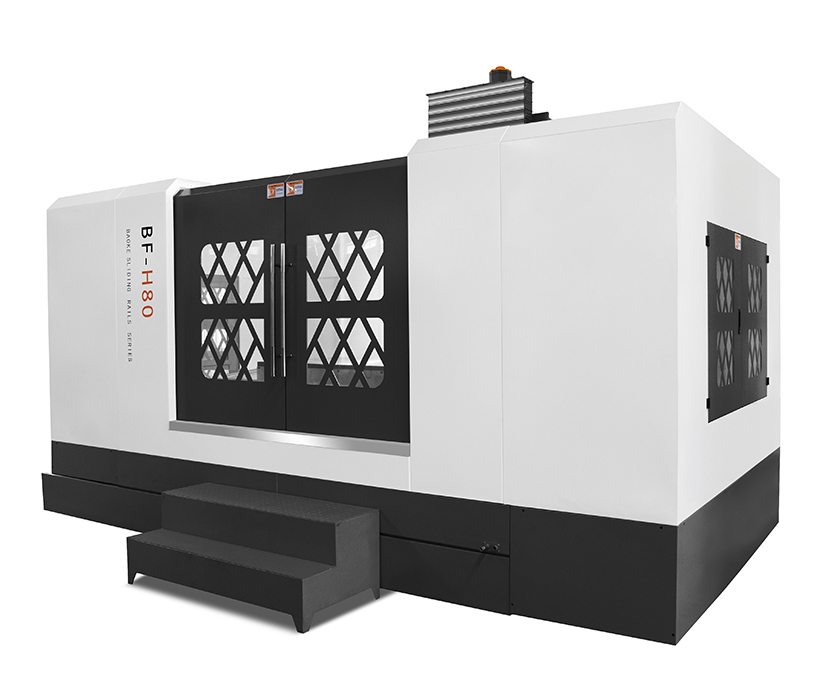

Overviews On Horizontal Machining Center(HMC)

In the previous, we have talked about the differences between vertical machining center(vmc) and horizontal machining center(hmc). in this paper, we will focus on the HMC.

What Is Horizontal Machining Center(HMC)?

The main axis of horizontal machining center is in a horizontal state, usually with a square table for indexing rotation. Generally has 3 ~ 5 motion coordinates, common is three linear motion coordinates plus a rotary motion coordinates, it can make the workpiece in a clamping in addition to the installation of the surface and the top surface of the remaining four surface processing, the most suitable for processing box parts. Generally with a indexing table or CNC conversion table, can process each side of the workpiece; It can also be used for joint motion of multiple coordinates in order to process complex spatial surfaces.

Some horizontal machining center with automatic exchange table, in the work of the workpiece in the working position of the workbench processing at the same time, can be located in the loading and unloading position of the workbench for loading and unloading of the workpiece, so as to greatly shorten the auxiliary time, improve processing efficiency.

Working Principle Of Horizontal Machining Center(HMC)

After the workpiece is clamped once in the machining center, the digital control system can control the machine tool according to different processing procedures, automatically select and replace the tool, automatically change the machine tool spindle speed, feed speed and the tool relative to the workpiece motion track and other auxiliary functions, in turn to complete the workpiece on multiple surfaces of multiple processes of processing. And there are a variety of knife change or knife selection function, so that the production efficiency is greatly improved.

Machining center due to the process of concentration and automatic tool change, reduce the workpiece clamping, measurement and machine tool adjustment time, so that the cutting time of machine tool to achieve about 80% of the machine time (ordinary machine tool is only 15 ~ 20%). At the same time, it also reduces the workpieces turnover, handling and storage time between processes, shorts the production cycle, and has obvious economic effect. Machining center is suitable for small and medium-sized batch production with complex parts shape, high precision requirement and frequent product replacement. Compared with vertical machining center, horizontal machining center complex structure, covers an area of large, the price is also higher, and horizontal machining center in the processing of inconvenient observation, parts clamping and measurement is not convenient, but easy to discharge chips when processing, favorable for processing.

Operation Rules Of Horizontal Machining Center(HMC)

The horizontal machining center usually produces metal products, and some casting products. And there is also metal CNC center. Here are some rules need to pay attention to.

- Wearing protective equipment before work as required.

- Checking whether the tool compensation, machine zeros and workpiece zeros are correct before starting.

- The relative position of each button should meet the operation requirements. Seriously prepare, input numerical control program.

- To check the equipment on the protection, insurance, signal, position, mechanical transmission part, electrical, hydraulic, digital display and other systems operating conditions, in all normal conditions can be cut.

- Before the machine tool test run, should check the lubrication, mechanical, electrical, hydraulic, digital display and other systems operating conditions, in all normal conditions can be cut.

- After the machine tool enters the processing operation according to the procedure, the operator is not allowed to contact the workpiece, cutting tool and transmission part of the movement, and is prohibited to transfer or take tools and other items across the rotating part of the machine tool.

- When adjusting machine tools, clamping workpiece and cutting tools and wiping machine tools, it must be stopped.

- Tools or other items should not be placed on electrical appliances, operating cabinets or protective covers.

- Do not use hands to remove iron filings directly, should use special tools to clean.

- If any abnormality or alarm signal is found, stop immediately and ask relevant personnel to check.

- It is not allowed to leave the working post when the machine is in operation. When leaving for some reason, the worktable should be placed in the middle position, and the knife bar should be returned. It must be stopped and the power supply of the host machine should be cut off.

Dongguan Baoke Precision Machinery Co., Ltd is a specialized CNC machining center manufacturer, don’t hesitate to contact us.