- NO63, XinTai Road, XinMaLian, DaLang Town, Dongguan City, Guangdong province

- info@baofengmachine.com

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

News

How to do Well the Maintenance of Horizontal Milling Machine?

The maintenance of horizontal milling machine is mainly to pay attention to cleaning, lubrication and correct operation.

Routine maintenance is divided into the following three stages:

- Before work starts. Check whether all parts and mechanisms of the machine tool are complete and whether all handle parts are normal; Clean all parts of the 4 axis horizontal milling machine tool, check all lubricating devices, and directly pour oil on the guide rail surface of the machine tool for lubrication; Start the machine at low speed and idle for a period of time.

- Work link. It is mainly for correct operation. It is not allowed to overload the 4 axis horizontal milling machine tool, and it is not allowed to use precision machine tools for rough machining. If abnormal conditions are found in the working process, the machine should be shut down for inspection.

- After the work is completed. Clean all parts of the 4 axis horizontal milling machine tool, move all moving parts of the machine tool to the specified positions, and turn off the power supply.

Maintenance precautions:

The horizontal machining center for sale is generally required to be maintained once by the operator after the cumulative operation of 800H, and the maintenance shall be carried out after the power supply is disconnected.

1.External maintenance. It is mainly used to clean the dirt and rust on the surface of the machine tool and maintain the cleanness of the transmission parts. Wipe the surface and cover of the machine tool to ensure that there is no rust or yellow spot; Wipe all exposed lead screws, polished rods and racks; Supplement all handles, screws, nuts and other mechanical parts to maintain the appearance of the machine tool clean.

2.Maintenance of headstock and feed gearbox. Lift each dust cover of the spindle box, check and adjust the V-belt and spindle box clamping pull rod. Clean all filters and oil tanks; Check the fastening condition of steel wire rope of counterweight; Wipe the sliding groove of the flat rotating disc and adjust the inlay strip.

3.Maintenance of workbench and guide rail. Wipe all parts of the worktable of the horizontal boring and milling machine, check and adjust the clearance between the retaining iron and the inlay strip; Check whether the guide rail is roughened, polish the burrs and wipe the guide rail.

4.Rear column maintenance. Wipe the surface of rear bearing seat and guide rail, and check and adjust the clearance of insert strip.

5.Lubrication system maintenance. Clean the felt and oil tank, and keep the oil hole and oil circuit unobstructed. Clean the cooling pump, filter screen and cooling box. Clean the filter and keep the oil window of the oil standard bright.

6.Electrical maintenance. Clean the electrical box and motor of the horizontal boring and milling machine. Check the position of the electrical device, and keep the electrical device fixed, safe and neat.

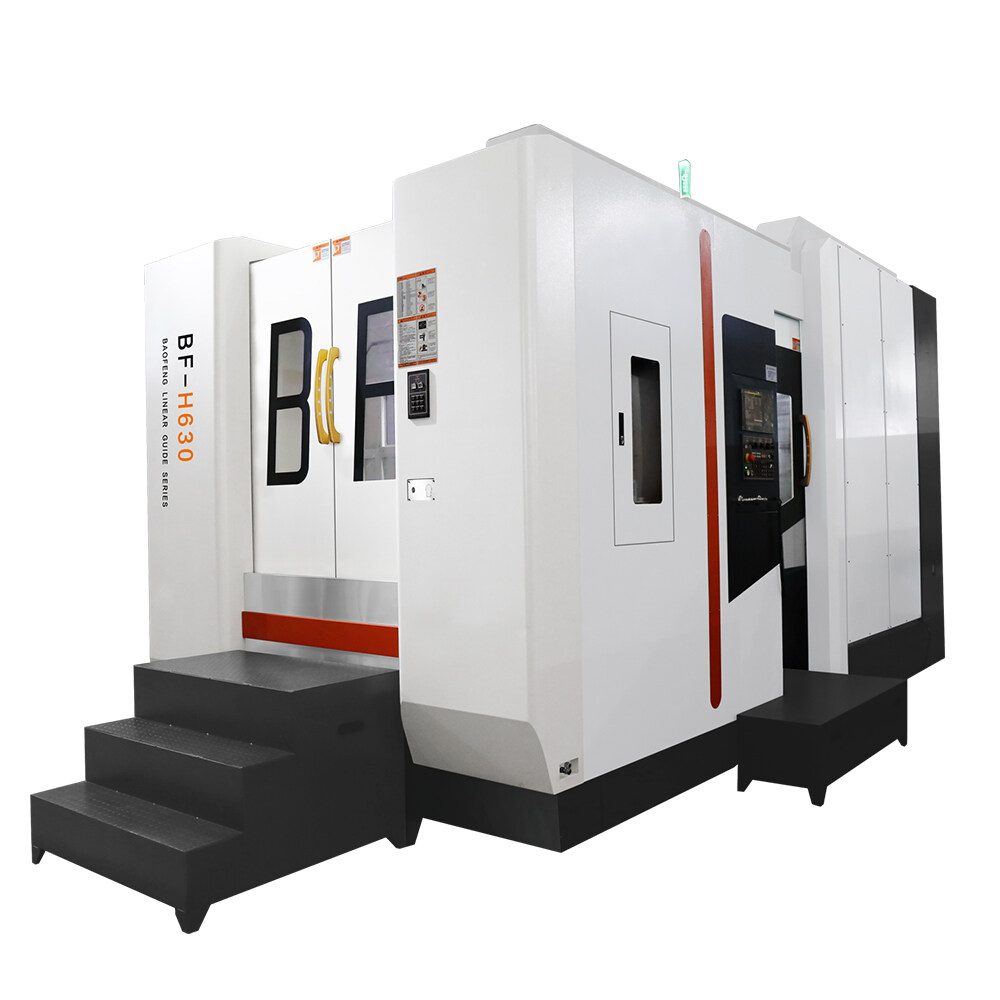

We are a horizontal milling center, 3 axis cnc milling machine suppliers. And we want to be your long-term partner, any interests, welcome to contact us.