- NO63, XinTai Road, XinMaLian, DaLang Town, Dongguan City, Guangdong province

- info@baofengmachine.com

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Double column machine center

Double column machine center

(17)BAOFENG BF-6029L Double Column Machining Center

We offer Taiwan gear type spindle box and Germany ZF gearbox to realize strong cutting, equipped with Taiwan right angle milling head to realize simple horizontal machining requirements, and equipped with Taiwan universal milling head to realize multiple angle machining requirements. Equipped with automatic pentahedron milling head to realize multiple dimension high precision machining.

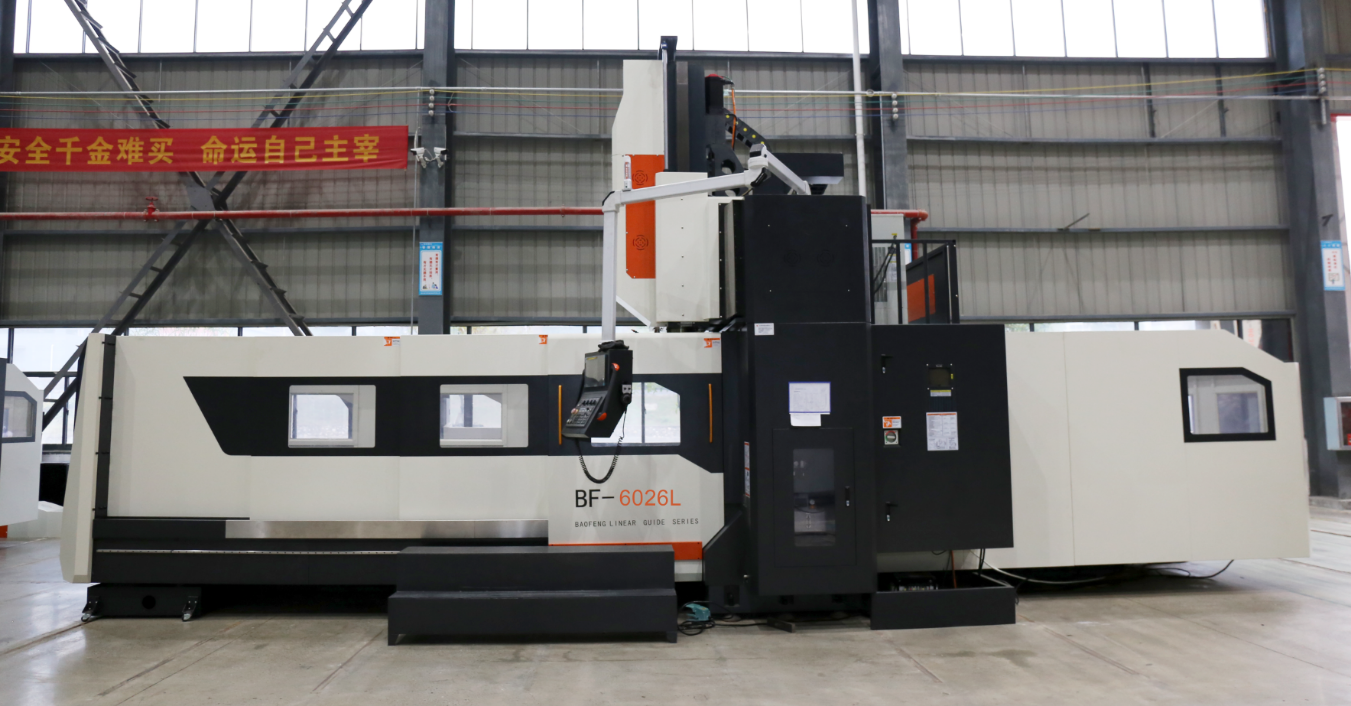

BAOFENG BF-6026L Double Column Machining Center

Double column machining centers are mainly used for the processing of large boxes, complex surface molds, large-shaped parts and plate parts. By adopting international dynamic rigidity design idea and optimizing moving parts on the basic of high rigidity structure symmetry high stability of traditional double column machining center, this series machines are mainly made of base,worktable,columns ,beam ,saddle ,hydraulic system ,lubrication system cooling and filtering system chip device CNC system and other parts.

BAOFENG BF-5026L Double Column Machining Center

Double-column machining center is mainly used for processing large-sized boxes and complex surface molds, large-sized parts and plate parts. The equipment uses two columns, linked by the gantry of the column, which can move both horizontally and obliquely, so that the movement of a U-shaped table can be achieved by moving only one column in planes of x, y and z. This machine has high precision and powerful cutting force.

BAOFENG BF-5029L Double Column Machining Center

Double-column machining center is mainly used for the processing of large boxes, complex surface molds, large-shaped parts. The main parts are bed and spindle, which are made from high quality materials. Also have a variety of technological equipment and appropriate accessories to ensure that the finished product is qualified.

BAOFENG BF-6032L Double Column Machining Center

The new CNC Woodworking Machine BF-6032L changes the game in ways that you never thought possible. Portal frame structure, traveling worktable (X-axis), spindle box traveling (Z-axis), saddle traveling on the beam (Y-axis), square ram design and twice speed-reducing with retarders offer low-speed constant torque and high-speed constant power cutting.

BAOFENG BF-8032L Double Column Machining Center

Baofeng CNC Double Column Vertical Machining Centers combine proven machine design with advance technology in control and manufacturing. Reliability and performance make this series a favorite among demanding CNC work shops and in-house productions alike.

BAOFENG BF-4029L Double Column Machining Center

Double column machining center is mainly used for the processing of large boxes, complex surface molds, large-shaped parts, and plate parts in the textile machinery, metallurgy, petrochemical, locomotive and other industries. Once clamping can meet the requirements of coarse, half finishing and finishing, can finish milling, drilling, tapping, boring, reaming and other processes

BAOFENG BF-3026L Double Column Machining Center

Our double column machining center is mainly used for the processing of large boxes, complex surface molds, large-shaped parts and plate parts. The X/Y-axis adopt super overloading linear rolling guideway, Z-axis adopts rectangular hardened and plastic hard guideway; high precision, high speed and strong cutting. Spindle box is equipped with hydraulic automatic balancing system which dynamically balances the self-weight of spindle box to guarantee processing accuracy and stability of the machine tool.

BAOFENG BF-4026L Double Column Machining Center

Double column machining center is mainly used for the processing of large boxes, complex surface molds, large-shaped parts, and plate parts. It can be used for the numerical control of parts to produce large-sized products with high processing accuracy, large dimensional stability and uniform roughness.

BAOFENG BF-3023L Double Column Machining Center

Double column machining center is mainly used for the processing of large boxes, complex surface molds, large-shaped parts. It can do turning, milling and drilling in 2D and 3D. Adopt gantry frame fixed beam structure, machine bed, and main parts use high-strength cast iron, ensure the stability of the machine during the long using term

BAOFENG BF-4023L Double Column Machining Center

When you need a machine tool to process your mid to large size workpiece, look no further than BAOFENG. Our Vertical Bridge Mill line offers the strength and speed to make short work of your toughest jobs. We start with HT300 castings, annealed to eliminate deformation caused by internal warpage and stress. driven by a powerful Fanuc motor,

BAOFENG BF-2518V Double Column Machining Center

Baofeng gantry milling center is mainly consists of bed, column and beam and etc.The parts adopt industrial-grade steel with high rigidity and high stability.It is widely used in mold, precision machinery field.It can realize the five-face processing at one time of clamping ,serving several purposes.It can effectively enhance the processing precision and processing efficiency.