CNC Drill Tap Center,Drill Tap Center Machine,5 Axis CNC Mill Cost,Machining Center 5 Axis

A CNC tapping center is a computer-controlled machine tool used to machine parts in a wide variety of industries, characterized by high speed, high accuracy, and high productivity.

Over the course of its development, the CNC tapping center has evolved to be one of the “all-in-one” machine tools, capable of performing a variety of tasks including milling and fine boring in addition to tapping. Coupling with CNC capability, CNC tapping centers are productive, reliable and are known for their superb machining capabilities.

CNC tapping machines are very useful tapping machinery that does a lot of machining jobs. Sometimes a CNC tapping machine can do more than one machining job such as drilling or chamfering. So what does a CNC tapping machine do? What is a CNC tapping process exactly? Simply put, tapping in the machining field in essence refers to the process of creating a thread into a hole.

A CNC tapping machine is the machine tool that performs such a process. Usually, a tapping machine works with other tools such as a lathe or a drill because a predrilled hole is needed so that the machine can create a thread into it.

CNC drilling machine

A CNC drilling machine is a computer-controlled machine that is used to drill holes into a workpiece with high precision and accuracy.

The machine consists of a drilling head, which holds the drill bit, and a worktable, which holds the workpiece. The drilling head is guided by a series of motors and actuators that are controlled by the computer program. The program specifies the coordinates of the holes to be drilled, the depth and diameter of the holes, and the speed and feed rate of the drill.

CNC drilling machines offer several advantages over traditional drilling machines, including greater precision, accuracy, and repeatability. They also require less operator skill and can perform drilling operations more quickly and efficiently.

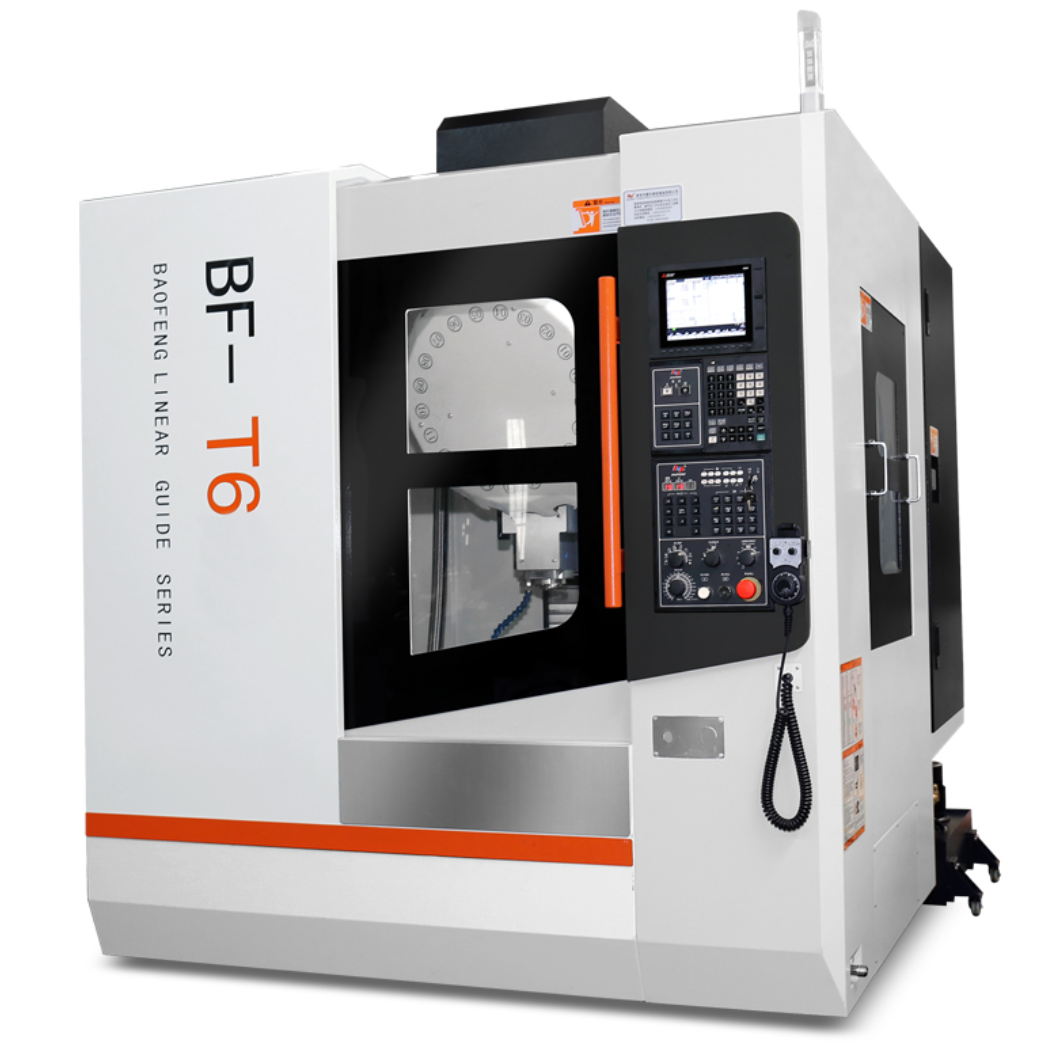

CNC drilling machine manufacturer

Baofeng CNC drilling machine manufacturer is a leading manufacturer of high-quality CNC drilling machines. our has several advantages that set it apart from its competitors, including:

Advanced Technology:

CNC drilling machines are designed using advanced technology that allows for precise and accurate drilling operations. The machines are equipped with high-quality components that are engineered to deliver reliable and consistent performance.

Customization: CNC drilling machines can be customized to meet the specific needs of customers. The company offers a range of options for drill bit size, drilling depth, and workpiece size, allowing customers to choose the configuration that best suits their needs.

Cost-effectiveness: CNC drilling machines are competitively priced, making them an affordable option for businesses of all sizes. The company also offers financing options and leasing programs to help customers manage the cost of purchasing a new machine.

After-sales service: CNC drilling machine manufacturer provides excellent after-sales service to its customers. The company has a team of experienced technicians who can provide technical support and assistance with machine maintenance and repair.

Reliable delivery: CNC drilling machine manufacturer has a strong supply chain management system that ensures timely delivery of machines to customers. The company has a reputation for delivering machines on time and in excellent condition.

Overall, Baofeng CNC drilling machine manufacturer is an excellent choice for businesses looking for high-quality, reliable CNC drilling machines. With its advanced technology, customization options, cost-effectiveness, after-sales service, and reliable delivery, the company is well-positioned to meet the needs of customers in a wide range of industries.