- NO63, XinTai Road, XinMaLian, DaLang Town, Dongguan City, Guangdong province

- info@baofengmachine.com

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

News

What are the Forms of 5 Axis Machining Centers?

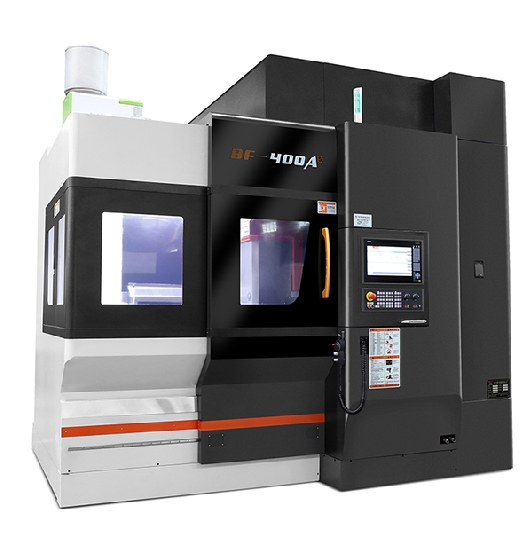

wholesale 5 axis machining center

Five-axis machining is a kind of NC machining. The machining centers we usually use now are generally three-axis and three linkage machining centers. The three-axis refers to the X-axis, Y-axis, and Z-axis of the machining center. Of course, there are also four-axis machining centers. Four-axis machining center refers to the X-axis, Y-axis, Z-axis, and axis, where an axis refers to the axis rotating around the X-axis. The five-axis machining center refers to the b-axis other than the X-axis, Y-axis, and Z-axis, and the b-axis refers to a rotation axis around the Y-axis. The technology has been widely used in high-precision instrument manufacturing fields such as shipbuilding, aerospace, automobile, light industry, medical treatment, etc.

In traditional mold processing, a three-axis machining center and vertical machining center are usually used to complete the milling of the workpiece. With the development of mold manufacturing and processing technology, the ball end milling cutter commonly used in traditional mold processing has obvious advantages. However, if the vertical machining center is used, its bottom linear speed is zero and its finish is poor. Therefore, the weakness of traditional mold processing gradually appears. The five-axis machining center can process different surfaces of the workpiece without changing the position of the workpiece on the machine tool, which can greatly improve the machining efficiency of prismatic parts.

To truly understand the five-axis machining center, we must first understand what a five-axis machine tool is. As the name suggests, the five-axis machine tool means that two rotating axes are added to the three commonly used linear axes of X, y, and Z. the two rotating axes of axis A, axis B, and axis C have different motion modes to meet the technical requirements of various products. In the mechanical design of the five-axis machining center, machine tool manufacturers have been unremittingly committed to developing new motion modes to meet various requirements. At present, various five-axis machine tools in the comprehensive market have various mechanical structures, but mainly in the following forms:

1.the two rotation coordinates directly control the direction of the tool axis (double pendulum form);

2.the two coordinate axes are on the top of the tool, but the rotation axis is not perpendicular to the linear axis (pendulum);

3.two rotation coordinates directly control the rotation of the space (in the form of double turntables);

4.the two coordinate axes are on the workbench, but the rotation axis is not perpendicular to the linear axis (inclined workbench);

5.one of the two rotating coordinates acts on the tool, and the other acts on the workpiece (one swing and one rotation).

We are a largest 5 axis cnc machine, 5 axis cnc milling machine manufacturers, our products satisfy our customers. And we want to be your long-term partner, any interests, welcome to contact us.