- NO63, XinTai Road, XinMaLian, DaLang Town, Dongguan City, Guangdong province

- info@baofengmachine.com

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

News

The Differences Between CNC Vertical Machining Center(VMC) And Horizontal Machining Center(HMC)

Vertical machining center and horizontal machining center are two common CNC machining center. Basic functions of them are similar, both are based on milling. But there also are differences between them. Many people do not know the differences between them and don’t know how to buy them. In this paper, we will introduce the difference between them. I hope this paper will be helpful for you and help you better choose them.

Vertical Machining Center(VMC)

Vertical machining center refers to the machining center whose spindle is vertical. Its structure form is fixed column, the worktable is rectangular, no indexing rotary function, suitable for processing plate, set, plate parts. It generally has three linear motion coordinate axes, and can be installed on the workbench along the horizontal axis rotation of the rotary table, in order to process spiral line parts.

Vertical machining center is easy to install card, easy to operate, easy to observe the processing situation, easy to debug the program, widely used. But by the column height and tool change device restrictions, can not process too high parts, in the processing of cavity or concave surface, chip is not easy to discharge, serious damage to the tool, damage has been processed surface, affect the smooth processing.

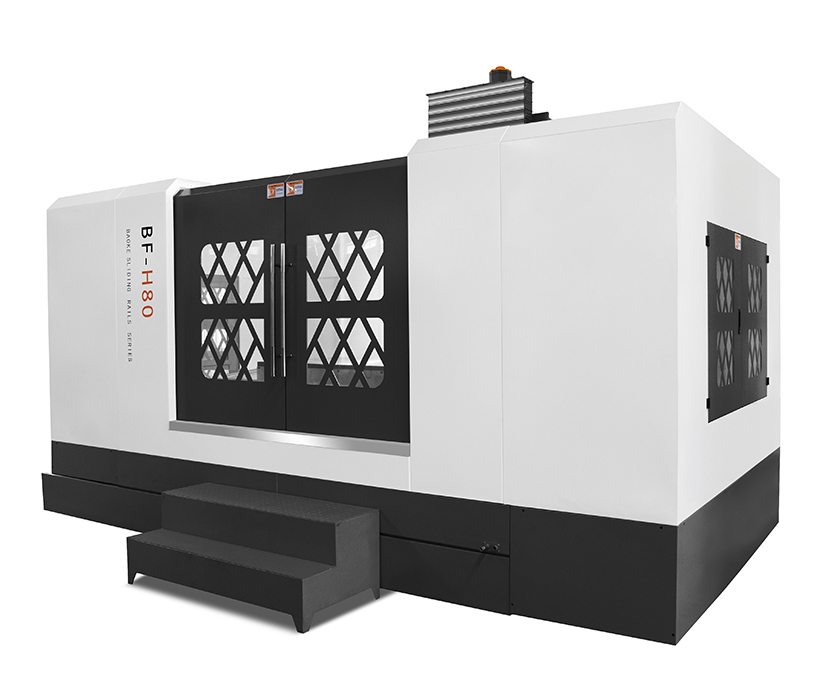

Horizontal Machining Center(HMC)

Horizontal machining center refers to the machining center with the horizontal spindle. Usually with automatic indexing rotary table, it generally has 3-5 motion coordinates, three linear motion coordinates plus a rotary motion coordinates is common. The workpiece in a card, complete in addition to the installation surface and the top surface of the remaining four surface processing, it is the most suitable for box parts. Compared with vertical machining center, horizontal machining center is easy to discharge chips when processing, but the structure is complex and the price is higher.

The Differences Between VMC And HMC

The Spindle Structure

The spindle of vertical machining center is vertical, while, the spindle for horizontal machining center is horizontal state.

Column Structure

The column of vertical machining center generally do not move. It's built as thick as possible for rigidity. There are also moving column type vertical machining center. Moving column vertical machining center table only do X or Y to the movement, the column will do Y or X to the corresponding movement. This kind of design has great power requirement to the drive motor of the column.

Horizontal machining center column must be moving column type. T type horizontal machining center column along the X to move, inverted T type horizontal machining center column along the Z to move. The structure of the moving column requires the column to be as light as possible under the premise of meeting the rigidity. The steel plate welding structure is commonly used in foreign processing centers to solve this problem.

Operating Conditions

Vertical machining center is easy to clamp, easy to operate, easy to observe the processing situation, easy to debug the program.

Horizontal machining center processing workpiece is generally large. It has a high degree of integration, difficult to clamp, not easy to monitor the processing process, relatively difficult to operate and debug.

The Workbench

Vertical machining center table is generally T - slot table of cross slide table structure. There are two sets of motion mechanism responsible for the mutually vertical direction of the work table movement, X direction of the work table is covered in the Y direction of the guide rail.

Horizontal machining center of the table only X or Y movement. The form of the table is generally the rotary table with the mesa of the dot matrix screw hole, and it is relatively easy to install the switching double table.

The Processing Object

Vertical machining center is limited by column height and tool change device, can not process too high parts, suitable for processing plate, set, plate parts. The workpiece volume is relatively small. If you want to realize the workpiece side processing, you must install Angle head or CNC turntable. If a rotary table along the horizontal axis is installed on the workbench, it can be used to process spiral line parts.

Horizontal machining center in a clamping can be completed in addition to the installation surface and the top surface of the remaining four surface processing. It is most suitable for processing box parts, add angle head can realize pentahedron processing.

In Conclusion

You can choose the machining center according to your products. I hope this paper can help you to choose them for the next time. And if you don’t know where to buy, you can find them in Dongguan Baoke Precision Machinery Co., Ltd. It is a reliable manufacturer.