- NO63, XinTai Road, XinMaLian, DaLang Town, Dongguan City, Guangdong province

- info@baofengmachine.com

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

News

Main Differences and Characteristics between Horizontal Milling Machine and Vertical Milling Machine

vertical machining center manufacturers in china

A milling machine is a kind of machine tool. Its spindle is parallel to the workbench, in a horizontal position, with a speed of 12 levels. It can process various planes, slopes, grooves, etc. with various cylindrical milling cutters, disc milling cutters, angle milling cutters, forming milling cutters, and end milling cutters. It can be divided into universal horizontal milling machines, horizontal lifting table milling machines, universal rotary head milling machines, etc.

Composition of milling machine

Now, let's see what constitutes a small cnc vertical machining center. Although the new milling centers have the ability to perform various operations, they are also more complex. Therefore, we can use more traditional milling machines to outline the composition of the machine.

Horizontal milling machine

The name of horizontal milling machine comes from the positioning of cutters - their axes are horizontal. Various cylindrical milling cutters, disc milling cutters, angle milling cutters, forming milling cutters and end milling cutters can be used to process various planes, slopes, grooves, etc.

The structure of horizontal milling machine is very simple. The tool is attached to the tool bar. When the tool needs to be replaced, the tool holder and gasket can be removed to replace the tool.

A vise is required to fix the workpiece on the workbench. Traverse moves the table on the X, y, and Z axes to move the workpiece.

Of course, newer machines look a little different, making them suitable for automation. The horizontal milling center may have multiple spindles with various tools on the spindles to speed up the turnaround time. In addition, the table and the tool can move in more directions, including the rotation axis.

However, the basic principle is the same. Understanding more traditional machines is enough to understand contemporary machines.

Advantages of small cnc vertical machining center:

- Provides the possibility to produce parts with fewer operations

- Ability to create more complex parts

- Longer tool life

- Better surface finish (the above 2 points are related to less chips falling on the cutting path)

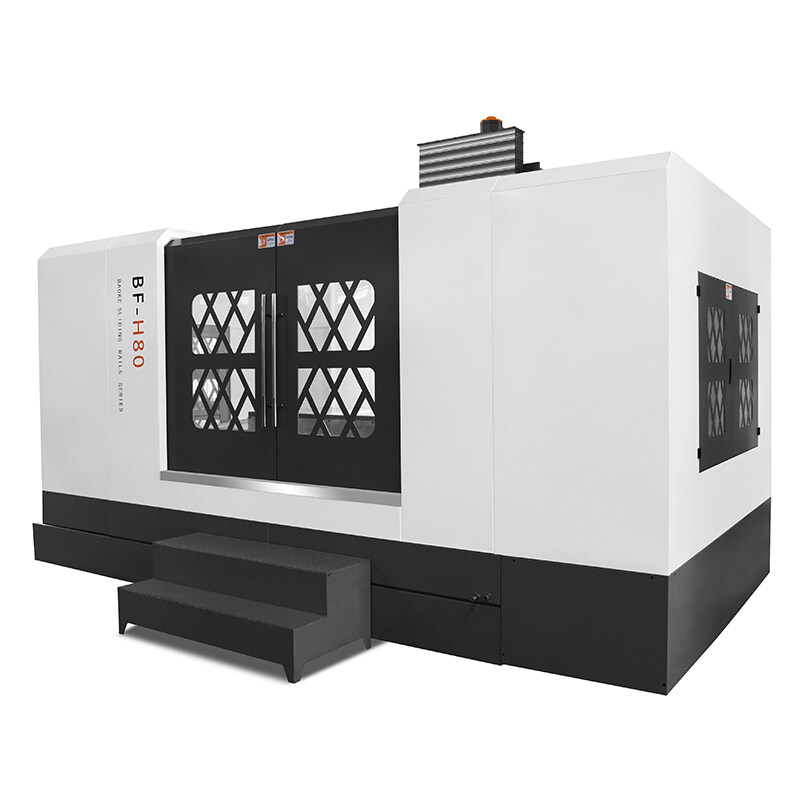

small cnc vertical machining center

Similarly, the name of the upright is self-evident. Because the positioning of the tool axis is vertical, it is more suitable for end milling.

The components of the vertical milling machine are similar to those of the horizontal milling machine. The head is at the end of the plunger. The spindle of the cutting tool is connected to the tool head.

The positioning of the worktable is the same as that of the horizontal milling machine, providing the ability to move the worktable in the same three directions.

Modern 5-axis vertical milling machines offer the possibility of rotating parts to obtain more channels and faster turnaround time. Automated actions lead to better accuracy, faster lead times and parts close to the same batch.

Advantages of small cnc vertical machining center:

- Cheaper than horizontal milling

- So more machining workshops can afford it

- Easier to use because the vertical provides better visibility and allows you to observe the milling process in real time

- More qualified mechanics

- The volume of the machine is smaller, and the space occupied in the NC machining workshop is less

Searching for a vertical machining center manufacturers in china, you can get high-quality products at a nice price.