- NO63, XinTai Road, XinMaLian, DaLang Town, Dongguan City, Guangdong province

- info@baofengmachine.com

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

News

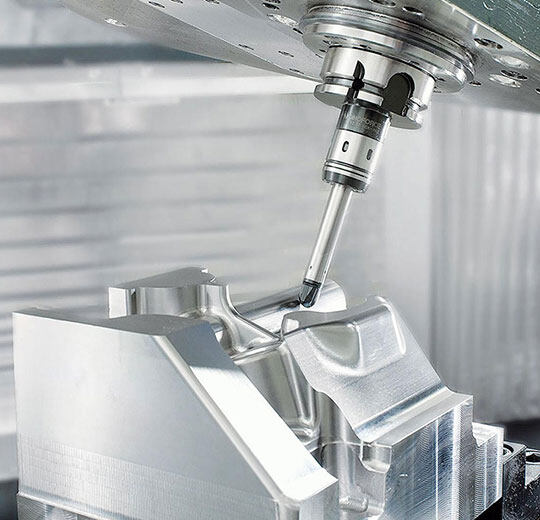

How to understand the application advantages of 5 axis machining center?

At present, the CAD system is mainly used to design the machining of parts. The part design is completed through reverse engineering and various tests. Because the complex surface of its workpiece is CAM software, the method to ensure the design and machining accuracy depends on CNC machining.

Now users understand the relationship between the application of the VMC 5 axis machine center in machining and machining quality. Therefore, How to better understand and use it?

Deep processing

When manufacturing parts, we should recognize the need to extend the rod and tools, but to use the 5 axis machine tool center to process the deep and steep cavity, it is necessary to create better conditions for the machining process, which can correctly shorten the length of the tool, to avoid the collision between the tool and the rod and the cavity wall, to reduce the fluctuation and damage of the tool during cutting, And obtain the service life of the tool, prolong the service time, and greatly improve the surface quality and processing efficiency.

Sidewall processing

To process the sidewall, the length of the tool used is greater than the depth of the sidewall, and the length of the tool also depends on the depth of the sidewall. If the length of the tool is increased, the resistance will be greatly reduced. If the length of the tool is greater than 3, double the diameter will lead to the phenomenon of the knife, and it will be difficult to ensure the quality of the workpiece. If the five-axis machining center of the program is used to process the sidewall, The spindle or workpiece may swing, and the milling cutter can be used to improve the quality of the workpiece and prolong the service life of the cutter.

Die plane processing

When the five-axis machining center is machined into a flat surface, to obtain good surface quality, the three-axis machining center must be finished with a ball cutter. In this case, the tool path must be increased, but the linear speed of the center rotation of the ball head cutting tool is almost zero. During machining, the tool is greatly damaged, the tool life is shortened, and the surface quality will also be reduced.

Today's five-axis machining center application can process the workpiece at a certain angle in the workpiece, which can improve the relative speed of the line between the workpiece and the blade. The spherical tip can not only use the tool but also prolong the service life and greatly improve the quality of the workpiece surface.

Our company supplies the best 5 axis machines. The company has exquisite technology, complete production, and testing equipment, and a strong technical force. It is your reliable partner. Our company sells well all over the country with low price and perfect service and meets the requirements of every customer to a great extent.