- NO63, XinTai Road, XinMaLian, DaLang Town, Dongguan City, Guangdong province

- info@baofengmachine.com

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

News

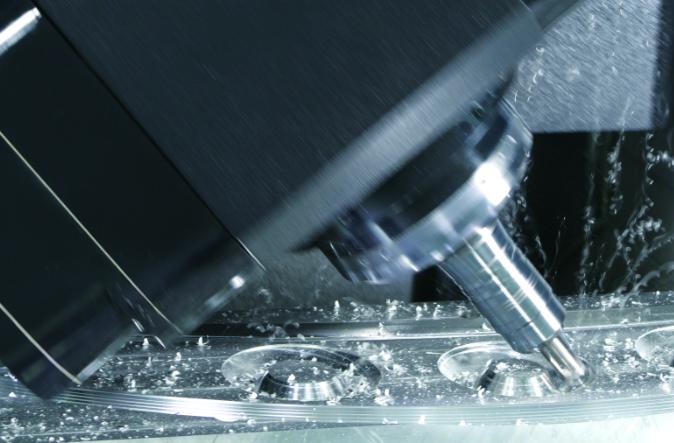

Gantry Type High Speed 5-Axis Machine Center

A gantry-type high-speed 5-axis machine center is a type of machine tool used in manufacturing and machining processes. It is characterized by its large, overhead gantry structure that supports the machine's spindle and tooling. The gantry structure allows for the machining of large parts with high precision and accuracy.

The "5-axis" in the name refers to the machine's ability to move the cutting tool along five different axes of motion: X, Y, Z, and two additional rotary axes. This enables the machine to create complex shapes and contours with a single setup, reducing the need for multiple machine setups and increasing efficiency.

The high-speed aspect of the machine refers to its ability to operate at fast speeds while maintaining accuracy and precision. This is achieved through the use of advanced control systems and cutting tools, as well as high-quality materials and construction methods.

Gantry-type high-speed 5-axis machine centers are commonly used in aerospace, automotive, and other industries that require the machining of large and complex parts with high precision and efficiency. They are also used in prototyping and research and development applications, as well as in production environments for high-volume manufacturing.

Advantages of gantry type high-speed 5-axis machine center

The gantry type high-speed 5-axis machine center offers several advantages over other types of machine tools.

1.One of the main benefits is its ability to reduce setup time and increase production efficiency by allowing for the machining of complex parts in a single setup. This not only saves time but also reduces the risk of errors that can occur during multiple setups.

2.Another advantage of the gantry type high-speed 5-axis machine center is its high level of accuracy and precision. The use of advanced control systems and high-quality materials and construction methods allows for precise and consistent machining of parts with complex geometries.

The high-speed capability of the machine enables manufacturers to reduce cycle times and increase throughput, ultimately leading to lower costs and higher profitability.

The gantry type high speed 5-axis machine center is a versatile and efficient machine tool that offers several advantages for manufacturers looking to increase their productivity and competitiveness in today's fast-paced manufacturing environment.

Feature Of gantry type high speed 5-axis machine center

There are several key features that make the gantry type high speed 5-axis machine center stand out among other types of machine tools.

1.One of these features is the overhead gantry structure itself, which provides excellent stability and rigidity during machining operations. This helps to ensure accurate and precise cuts, even at high speeds and with heavy workpieces.

2.Another important feature of the gantry type high speed 5-axis machine center is its advanced control system. This system allows for precise control of the machine's axes of motion, as well as the cutting tool itself. The control system can also be programmed with advanced tool paths and machining strategies, further enhancing the machine's efficiency and productivity.

The cutting tool itself is another key feature of the gantry type high speed 5-axis machine center. These machines are often equipped with high-speed spindles and advanced cutting tools that can quickly and accurately remove material from the workpiece. The tools are also designed to minimize vibration and chatter, which can lead to poor surface finish and reduced accuracy.

The gantry type high speed 5-axis machine center is often equipped with advanced safety features that protect the operator and the machine itself. These can include automatic tool changers, safety interlocks, and built-in sensors that monitor the machine's performance and alert the operator to any issues or potential problems.

The gantry type high speed 5-axis machine center is a powerful and sophisticated machine tool that offers a range of advanced features and capabilities for manufacturers looking to improve their efficiency, productivity, and competitiveness.

Applications of the gantry type high speed 5-axis machine center

When it comes to applications, the gantry type high speed 5-axis machine center is ideal for machining large and complex parts, such as aerospace components, automotive parts, and molds for injection molding. It can also be used for prototyping and research and development, as well as in production environments for high-volume manufacturing.

1.In the aerospace industry, the gantry type high speed 5-axis machine center is used for machining components such as airplane wings, engine parts, and landing gear. The ability to machine large, complex parts with high accuracy and precision is crucial in this industry, where safety and reliability are paramount.

2.In the automotive industry, the gantry type high speed 5-axis machine center is used for machining engine blocks, transmission cases, and other critical components. The high speed and accuracy of the machine make it ideal for producing high-quality parts quickly

and efficiently.

3.In the mold-making industry, the gantry type high speed 5-axis machine center is used for producing injection molds for plastic and other materials. The ability to create complex shapes and contours with a single setup reduces the need for multiple setups and increases efficiency, while the high speed and accuracy of the machine ensure consistent quality in the final product.

The gantry type high speed 5-axis machine center is a versatile and powerful machine tool that offers a range of advanced features and capabilities for a variety of applications. Its ability to machine large and complex parts with high accuracy and precision make it an indispensable tool in many industries.

When selecting a gantry type high speed 5-axis machine center, there are several factors to consider.

1.One of the most important is the size and weight capacity of the machine, as this will determine the types of parts that can be machined. It's also important to consider the spindle speed and cutting tool capabilities, as well as the type and quality of the control system.

2.Another important consideration is the level of automation and flexibility offered by the machine. Many gantry type high speed 5-axis machine centers are equipped with automatic tool changers, pallet changers, and other features that can reduce setup time and increase productivity. The ability to quickly and easily reprogram the machine for different parts and applications is also important for maximizing efficiency and versatility.

3.Cost is also an important consideration when selecting a gantry type high speed 5-axis machine center. These machines can be expensive, but the investment can pay off in increased productivity, reduced cycle times, and higher quality parts.

4.It's important to consider the reputation and support of the manufacturer when selecting a gantry type high speed 5-axis machine center. Choosing a reputable manufacturer with a strong track record of quality and service can help ensure that the machine will perform reliably and efficiently for many years to come.

5.Maintenance and upkeep are also important factors to consider when selecting a gantry type high speed 5-axis machine center. These machines require regular cleaning and lubrication to maintain their accuracy and precision over time. It's also important to follow the manufacturer's recommended maintenance schedule and to replace worn or damaged parts as needed.

Training and support for operators and maintenance personnel are also important considerations. Many manufacturers offer training programs and support services to help ensure that operators and maintenance personnel are properly trained and equipped to operate and maintain the machine.

In terms of safety, the gantry type high speed 5-axis machine center should be equipped with safety features such as safety interlocks, emergency stop buttons, and automatic tool changers to minimize the risk of injury to operators and damage to the machine.

The gantry type high speed 5-axis machine center is a versatile and powerful machine tool that offers a range of advanced features and capabilities for a variety of applications. When selecting a machine, it's important to consider factors such as size and weight capacity, spindle speed and cutting tool capabilities, level of automation and flexibility, cost, reputation and support of the manufacturer, maintenance and upkeep requirements, and safety features. By carefully considering these factors, manufacturers can select a machine that meets their specific needs and helps them improve their efficiency, productivity, and competitiveness in today's fast-paced manufacturing environment.

As technology advances, the capabilities and features of gantry type high speed 5-axis machine centers continue to evolve. For example, some newer machines are equipped with advanced sensors and monitoring systems that can detect and correct errors in real time, reducing downtime and improving productivity.

Another trend in the industry is the use of artificial intelligence and machine learning to optimize machining processes and improve efficiency. By analyzing data from sensors and other sources, these systems can automatically adjust cutting parameters and other variables to improve quality and reduce cycle times.

In addition, the trend towards Industry 4.0 and smart manufacturing is driving the integration of gantry type high speed 5-axis machine centers with other machines and systems in the production process. This allows for greater automation and flexibility, as well as real-time monitoring and control of production processes.

Overall, the gantry type high speed 5-axis machine center is a key tool in modern manufacturing, offering advanced capabilities and features that enable manufacturers to produce complex and high-quality parts quickly and efficiently. As technology continues to advance, the capabilities and applications of these machines will only continue to grow, making them an essential tool for manufacturers in a wide range of industries.