- NO63, XinTai Road, XinMaLian, DaLang Town, Dongguan City, Guangdong province

- info@baofengmachine.com

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

News

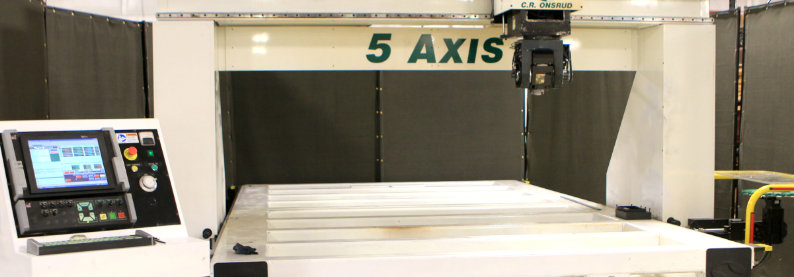

China 5-axis cnc machining center

China has rapidly developed into a global manufacturing hub, with its CNC machining industry being an important part of the country's manufacturing ecosystem. In recent years, China's CNC machining centers have been gaining popularity among manufacturers worldwide, thanks to their superior precision, accuracy, and efficiency.

Among the various types of CNC machining centers available, the 5-axis CNC machining center is one of the most advanced and sought-after machines, especially in high-precision industries like aerospace, automotive, medical, and mold making. we will explore the China 5-axis CNC machining center market, including its current state, trends, challenges, and opportunities.

Overview of China's 5-axis CNC machining center market

According to a report by the China Machine Tool Industry Association (CMTBA), the output of CNC machine tools in China reached 307,900 units in 2020, with a total sales revenue of 183.75 billion yuan ($28.25 billion). Among these, the 5-axis CNC machining center is becoming increasingly popular due to its versatility, efficiency, and precision.

The Chinese 5-axis CNC machining center market is dominated by domestic players, with companies like Dalian Machine Tool Group, Shenyang Machine Tool Co., Ltd., and Beijing Jingdiao Group Co., Ltd. being the major players. However, foreign players like DMG MORI, Mazak, and Haas Automation also have a significant presence in the market.

The 5-axis CNC machining center market in China is segmented based on type, application, and end-use industry. The types of 5-axis CNC machining centers available in China include horizontal, vertical, and hybrid machining centers. The most common applications of 5-axis CNC machining centers in China are mold making, aerospace, automotive, medical, and general manufacturing.

Trends in China's 5-axis CNC machining center market

a) Increasing demand for high-precision and complex parts

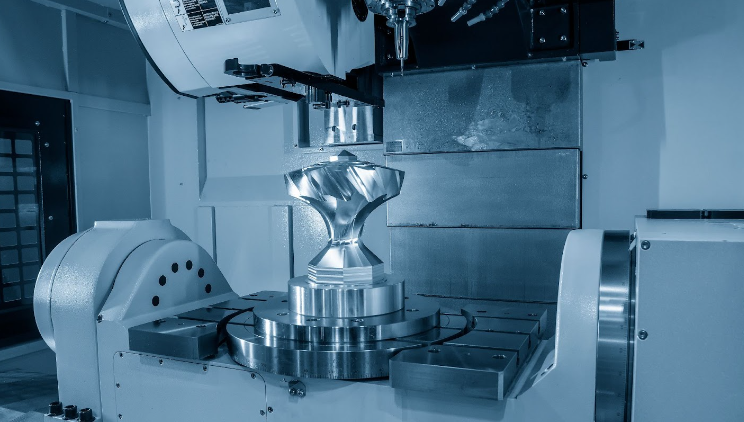

One of the main trends in China's 5-axis CNC machining center market is the growing demand for high-precision and complex parts. The aerospace and medical industries, in particular, require components with intricate geometries and tight tolerances, which can only be achieved with advanced 5-axis machining centers. This trend is driving the development of more advanced and sophisticated 5-axis CNC machining centers in China.

b) Integration with Industry 4.0 technologies

Another trend in China's 5-axis CNC machining center market is the integration of Industry 4.0 technologies like AI, IoT, and big data analytics. Chinese manufacturers are increasingly adopting smart manufacturing techniques to improve efficiency, reduce costs, and enhance quality control. 5-axis CNC machining centers that are equipped with advanced automation features, data collection, and real-time monitoring capabilities are in high demand in the Chinese market.

c) Focus on environmentally friendly machining

As environmental concerns become more pressing, Chinese manufacturers are adopting more sustainable practices, including environmentally friendly machining. 5-axis CNC machining centers that are equipped with energy-efficient features, such as regenerative braking systems, are gaining popularity in the Chinese market.

Challenges in China's 5-axis CNC machining center market

a) Lack of skilled labor

One of the main challenges facing China's 5-axis CNC machining center market is the shortage of skilled labor. The high precision and complexity of 5-axis machining require experienced and well-trained operators, programmers, and technicians. However, the rapid expansion of the industry has outpaced the availability of skilled labor, leading to a shortage of talent.

b) Increasing competition

The 5-axis CNC machining center market in China is highly competitive, with both domestic and foreign players vying for market share. As the market becomes more crowded, companies are under pressure to differentiate themselves and offer unique value propositions.

c) Rising material and production costs

The cost of raw materials and production in China is increasing, which is a challenge for manufacturers of 5-axis CNC machining centers. The increasing cost of raw materials, such as steel, aluminum, and copper, is driving up the cost of producing 5-axis CNC machining centers, which is putting pressure on manufacturers to maintain competitive prices.

Opportunities in China's 5-axis CNC machining center market

a) Growing demand from emerging industries

China's 5-axis CNC machining center market is expected to grow in the coming years, driven by increasing demand from emerging industries like renewable energy, 3D printing, and robotics. These industries require high-precision and complex parts, which can only be produced with advanced 5-axis CNC machining centers.

b) Expansion of the aerospace and defense industries

The aerospace and defense industries are growing rapidly in China, driven by increased government

investment and a growing middle class. This growth is driving demand for advanced 5-axis CNC machining centers, which are required to produce high-precision components for aircraft and defense systems.

c) Adoption of new materials

The adoption of new materials like composites, ceramics, and super alloys is driving demand for advanced 5-axis CNC machining centers. These materials are difficult to machine using traditional methods and require advanced machining techniques, which can only be achieved with 5-axis CNC machining centers.

Manufacturers can differentiate themselves by focusing on innovation, product quality, and after-sales service. They can also expand their product offerings to cater to the specific needs of different industries and applications. For example, some manufacturers are developing 5-axis CNC machining centers specifically for the medical industry, which require high-precision machining of complex parts.

The government is also playing a significant role in promoting the development of the 5-axis CNC machining center industry. The "Made in China 2025" initiative, launched in 2015, aims to transform China from a low-cost manufacturing hub to a high-tech manufacturing powerhouse. The initiative has identified 10 key industries, including aerospace, robotics, and medical devices, where China aims to become a world leader. The development of advanced 5-axis CNC machining centers is a critical component of this initiative, and the government has provided funding and other incentives to support the industry's growth.

The 5-axis CNC machining center market in China is an attractive opportunity for manufacturers, driven by increasing demand from high-precision industries like aerospace, medical, and mold making. While the market is dominated by domestic players, foreign players also have a significant presence. The industry faces challenges like the shortage of skilled labor and rising production costs, but there are significant opportunities for manufacturers to differentiate themselves and offer unique value propositions to customers. The government's support through initiatives like "Made in China 2025" is also helping to drive the industry's growth. Overall, the outlook for the 5-axis CNC machining center market in China is positive, and manufacturers who can adapt to the changing market dynamics and innovate will be well-positioned to succeed.