- NO63, XinTai Road, XinMaLian, DaLang Town, Dongguan City, Guangdong province

- info@baofengmachine.com

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

News

Advantages and Meaning of 5 Axis Milling Machine

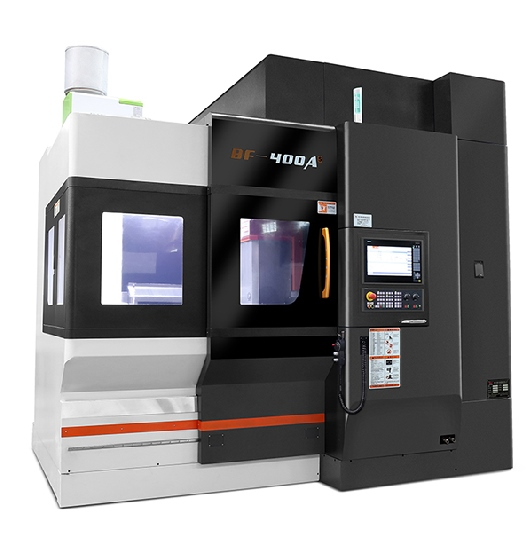

Five-axis machining is a general abbreviation of five-face machining technology and five-axis linkage machining technology. As the leading 5 axis milling center supplier, we want to talk about the advantages and meaning of 5 axis milling machine.

Meaning of five-axis milling

Five-side machining technology is used for complex polyhedral parts. Under the condition of one-time clamping, the milling, drilling, and boring of all planes except the installation base plane can be easily completed through the additional machine tool rotating shaft;

Not only that, but also when machining the inclined plane, through the rotation of the tool or workpiece, the tool can be better close to the machining surface and shorten the extension length of the tool, which is conducive to improving the cutting ability and tool life;

In addition, it can also solve the machining of concave surfaces which can not be solved by relying on the movement of the linear axis.

Five-axis linkage machining technology refers to the machining technology that a complex surface needs five independent axes to carry out NC interpolation movement together to obtain a smooth surface. In theory, any complex surface can be represented by X, y, and Z coordinates, but the actual machining tool is not a point, but an entity with a certain size. To avoid the interference between the tool and the machining surface when machining the space distorted surface and ensure the consistency of the cutting conditions of each point of the surface, It is necessary to adjust the included angle between the tool axis and the normal vector of the surface in the 2D direction.

Advantages of five-axis combined machine

Advantage 1: it can process continuous and smooth free-form surfaces that cannot be processed by general three-axis NC machine tools or are difficult to be clamped at one time.

Such as the blades of aero-engines and steam turbines, screw thrusters for ships, and many shells and molds with special curved surfaces and complex cavities and holes. When machining with a five-axis linkage machine tool, since the pose angle of the tool/workpiece can be adjusted at any time during the machining process, the interference of the tool and workpiece can be avoided and all machining can be completed at one time.

Advantage 2: it can improve the machining accuracy, quality, and efficiency of the spatial free-form surfaces.

Advantage 3: it is in line with the development direction of machine tools that can complete all or most of the processing of workpieces at one time.

Because with the development of science and technology and the improvement of people's material living standards, people have higher requirements for product performance and quality, and more diversified and personalized forms.

To further improve the performance and quality of products and fully meet the various requirements of users, not only aviation and aerospace products and vehicles (such as cars, ships, ships, etc.), but also precision instruments, meters, medical and sports equipment, household and office appliances, children's toys, and other product parts are increasingly made of integral materials, It also contains many kinds of complex surfaces, inclined holes, inclined planes and so on.

To solve these problems, it is necessary to develop machine tools that can concentrate processes for high-precision, efficient and compound processing, to realize that all or most of the processing can be completed at one time. This has become the general trend of today's machine tool development, and the five-axis machine tool equipped with high-speed machining capacity fully meets the trend of this development requirement, and may also be the best scheme choice.

Because it not only has the main functions required by modern production and processing equipment, but also the work efficiency of a five-axis machine tool is about equivalent to two three-axis processing machines, and even more machine tools can be saved.

Advantage 4: advantages of mold processing.

In traditional mold processing, the vertical machining center is generally used to complete the milling of the workpiece. With the continuous development of mold manufacturing technology, some weaknesses of the vertical machining center itself are becoming more and more obvious. Ball end milling cutter is widely used in modern mold processing. The benefits of a ball-end milling cutter in mold processing are very obvious.

However, if a vertical machining center is used, the linear speed of its bottom surface is zero, so the finish of the bottom surface is very poor. If four and five-axis linkage machine tool processing technology is used to process molds, the above shortcomings can be overcome.

We are the professional mill turn center exporter, we supply c axis milling and other high-quality products, if you need, plz feel free to contact us.