- NO63, XinTai Road, XinMaLian, DaLang Town, Dongguan City, Guangdong province

- info@baofengmachine.com

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Vertical Machine center

Vertical Machine center

(28)The flexibility of a vertical machining center can increase the productivity of your operation.

Regardless of your industry, this multifunction machine can perform a variety of mechanical operations. Many centers feature multiple tool changers and options to increase productivity. Having a vertical machining center with different options and features is an excellent way to reduce costs and increase productivity.

The flexibility of your vertical machining center will depend on the tooling you use and the amount of work that your machine can handle. The maximum size of a workpiece is one factor to consider when deciding which type of machining tool to buy. The flexibility of your VMC will also depend on the tooling and options you have available.

For a variety of machining needs, including high-speed, heavy-duty, and 5-axis machining, baofeng’s complete line of vertical machining centers delivers lasting performance. Due to a vibration-dampening Meehanite cast iron base and large precision spindle bearings, we offer shops increased rigidity while sustaining higher load capacities. Every vertical machining center features fully-equipped Fanuc controls for maximum machining capabilities.

A VMC is a machine with a CNC (Computer Numerical Control) controller. As mentioned, the cutting head in this milling machine is vertical and is a particular type of milling machine where the spindle runs in a vertical axis known as the “z” axis. They are typically enclosed and most often used for cutting metal.

The Vertical Machine series models employ a high-rigidity casting bed to ensure stable machining. The models demonstrate various machining from high-speed, high-quality machining using a high-speed spindle with the max. speed of 24,000 min-1 (option) to heavy-duty machining using a powerful spindle with a torque of up to 303 Nm (option).

The model is equipped with an innovative cooling system on the spindle, linear guides and ball nut to control thermal displacement, ensuring high-precision machining for a long term.

Machine Characteristics of Vertical Machining Center

The vertical machining center has the advantages of convenient clamping, easy operation, easy observation of machining conditions and easier debugging program, so it is widely used. However, this type of machine is limited by the height of the column and the tool change device, so it can not process too high parts. When processing the cavity or concave surface, the chip is not easy to discharge, which will damage the tool and the machined surface in serious cases, affecting the smooth progress of processing. It can be solved by installing automatic chip conveyor and oil cooler.

3/4/5 axis High Rigidity Vertical CNC Machine Center BK-1370B

BK-1370B is mainly used for rough machining of parts and molds with large quantity of material removal which is applied in rough machining of general machinery, metal parts, injection mold, casting steel mold, and complex parts. And it can realize drilling, milling, boring, reaming and other machining processes. The machine tool spindle is modular type chuck structure that equipped with a high-precision indexable sleeve to make the tool holder more convenient to combine and change quickly.

High Speed Box way machining center Vertical CNC Machinery for Mold Processing

BK-1170B is mainly used for rough machining of parts and molds with large quantity of material removal which is applied in rough machining of general machinery, metal parts, injection mold, casting steel mold, and complex parts. And it can realize drilling, milling, boring, reaming and other machining processes. It’s equipped with a rugged structure, functional safety devices and reliable performance to guarantee the efficiency of various processes.

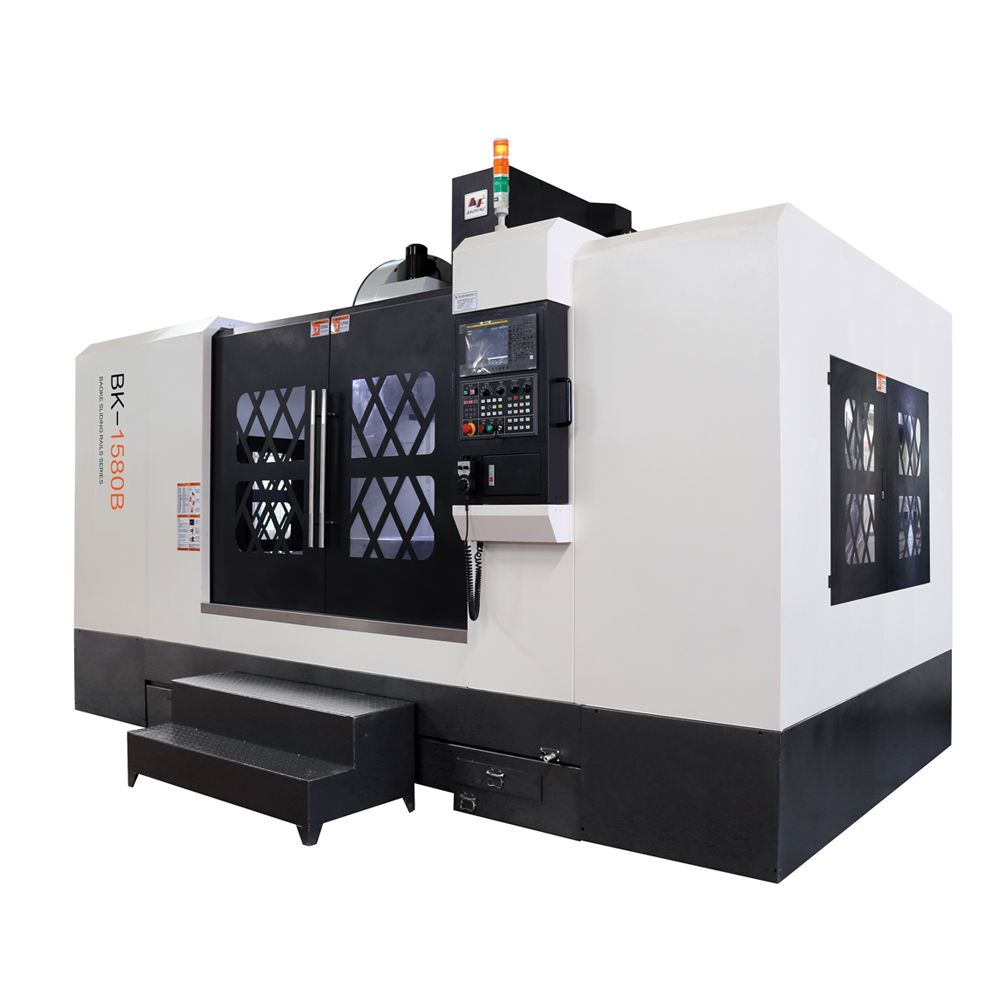

High Quality Vertical CNC Machine Center High Rigidity Factory Price Vmc

BK-1580B pneumatic high-speed milling machine is mainly used for rough machining of parts and molds with large quantity of material removal which is applied in rough machining of general machinery, metal parts, injection mold, casting steel mold, and complex parts. And it can realize drilling, milling, boring, reaming and other machining processes.

Excellent Performance Box way machinery BK-1890B CNC Machine Center

BK-1890B is a high-end CNC machine tool. It can be used in rough machining, precision machining and special processing of parts.The machine can realize drilling, milling, boring, reaming and other machining processes.