- NO63, XinTai Road, XinMaLian, DaLang Town, Dongguan City, Guangdong province

- info@baofengmachine.com

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

vertical milling machine suppliers

L series linear way machining center BK-850L

The BK-850L is mainly used for the automatic mass processing of parts and molds, such as complex cams, sample board, dies and arcs. It can be widely applied in electronics, machinery, automotive, motorcycle, automation, medical equipment and other industries. With high processing efficiency at a very reasonable cost, this machine has many competitive advantages.

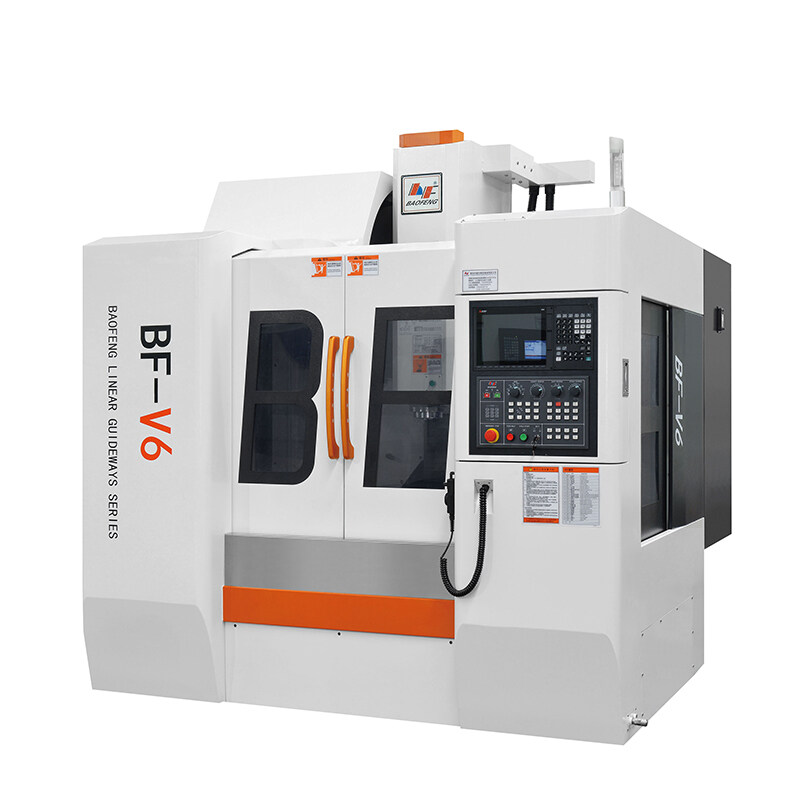

BAOFENG V6 Linear way machining center

With the rigidity, stability, high speed and high precision moving parts, it could accept high inertia gravity and even a long time processing. The strongest column and double-layerd base could bear higher inertia gravity and improve dynamic responsiveness of the whole machine. The spindle vibration is smaller than most popular V4 vibration standard, providing better surface processing performance.. The fastest tapping speed can reach 6000 rpm and the smallest tooth can attack M1.2

BAOFENG V13 Linear way machining center

Adopt large span support, according to the principle of Bessel physical deformation resistance, so that the casting has the best deformation resistance structure. The body is designed by Finite Element Analysis(FEA) to ensure the stability and rigidity of the mechanism.

High Speed Box way machining center Vertical CNC Machinery for Mold Processing

BK-1170B is mainly used for rough machining of parts and molds with large quantity of material removal which is applied in rough machining of general machinery, metal parts, injection mold, casting steel mold, and complex parts. And it can realize drilling, milling, boring, reaming and other machining processes. It’s equipped with a rugged structure, functional safety devices and reliable performance to guarantee the efficiency of various processes.

High Rigidity Box way machinery Vertical CNC Machine Center BK-850B

BK-850B is mainly used for rough machining of parts and molds with large quantity of material removal. It can realize drilling, milling, boring, reaming and other machining processes according to user’s needs. Then the machined products have high precision and good surface finish.