- NO63, XinTai Road, XinMaLian, DaLang Town, Dongguan City, Guangdong province

- info@baofengmachine.com

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

horizontal shaper machine manufacturer

Main features of automatic horizontal vacuum forming machine:

1. Precise computer control system, multi-language display, intelligent control of graphic interface, realize man-machine dialogue;

2. It can implement four operating modes: fully automatic, semi-automatic, intermediate start and manual operation;

3. Direct hydraulic drive, large and balanced clamping force, multi-stage pressurization, ideal speed adjustment function, which greatly shortens the time of mold opening and closing;

4. The vacuum system greatly shortens the product forming time and makes demoulding easy and convenient;

5. The reasonable configuration of steam, cooling and exhaust drainage brings the excellent quality of the product;

6. The computer memorizes the technical parameters of different mold models, which can be called at any time when changing the mold;

7. It can realize product control and management in computer production;

8. The whole machine has a high degree of automation, simple operation and convenient maintenance.

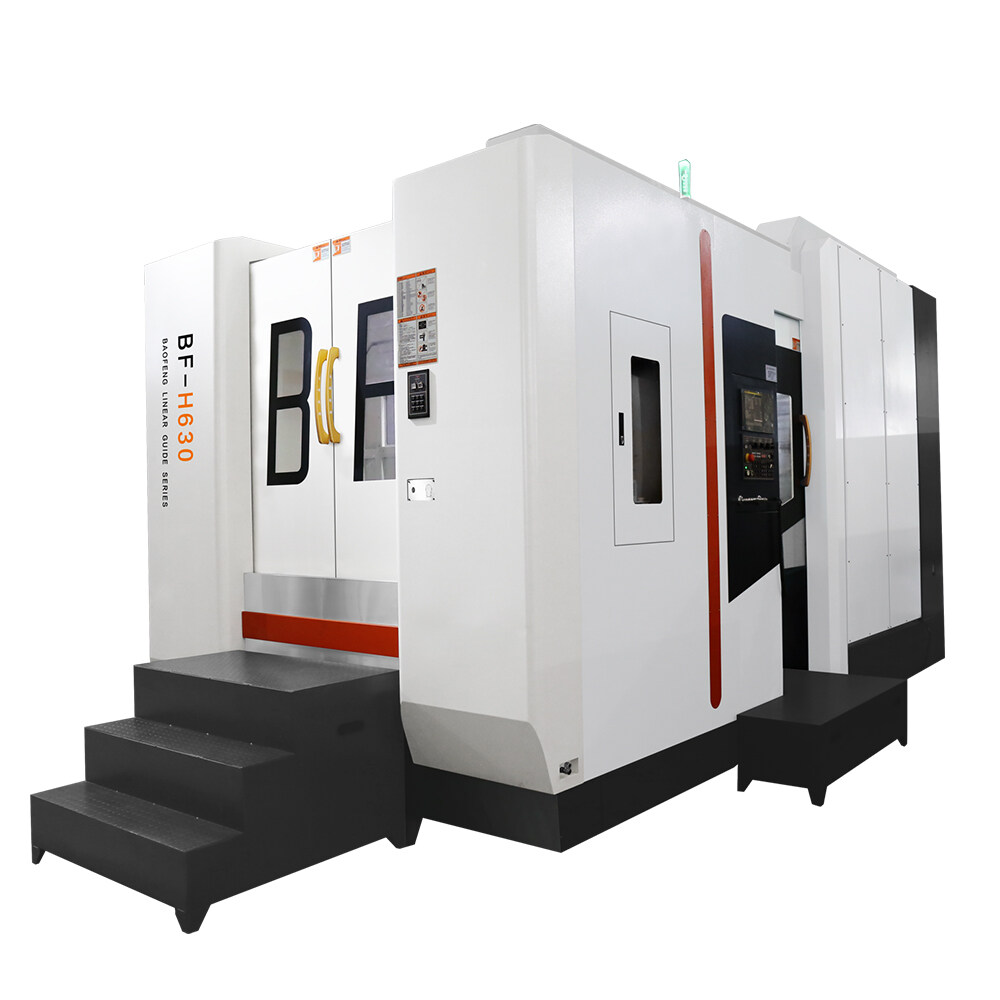

horizontal shaper machine manufacturer

A horizontal CNC milling machine is a CNC-controlled machine used to remove material from a workpiece.

When choosing a horizontal CNC milling machine, make sure that the machine has a table. The table provides a sturdy platform to clamp the work piece and can also hold fixtures and vices. Most tables feature T-slots to allow clamping a vice or part. Many tables also have pallets with tap-holes for greater flexibility.

Some manufacturers also produce horizontal CNC milling machines for the job shop environment. Some models come with integrated 4-th axis platters, which simplify large mold machining. Baofeng horizontal machining centers offer superior capabilities at a low price and make an excellent choice for a job shop.

Horizontal Machine Center BK-1814L

The T-type base, full support structure for each axis, makes the machining accuracy more stable; Large capacity tool magazine and strong processing adaptability. Single and double exchange pallets are optional. Automatic chip removal reduces cleaning downtime. Wide processing range suitable for processing all kinds of mechanical parts

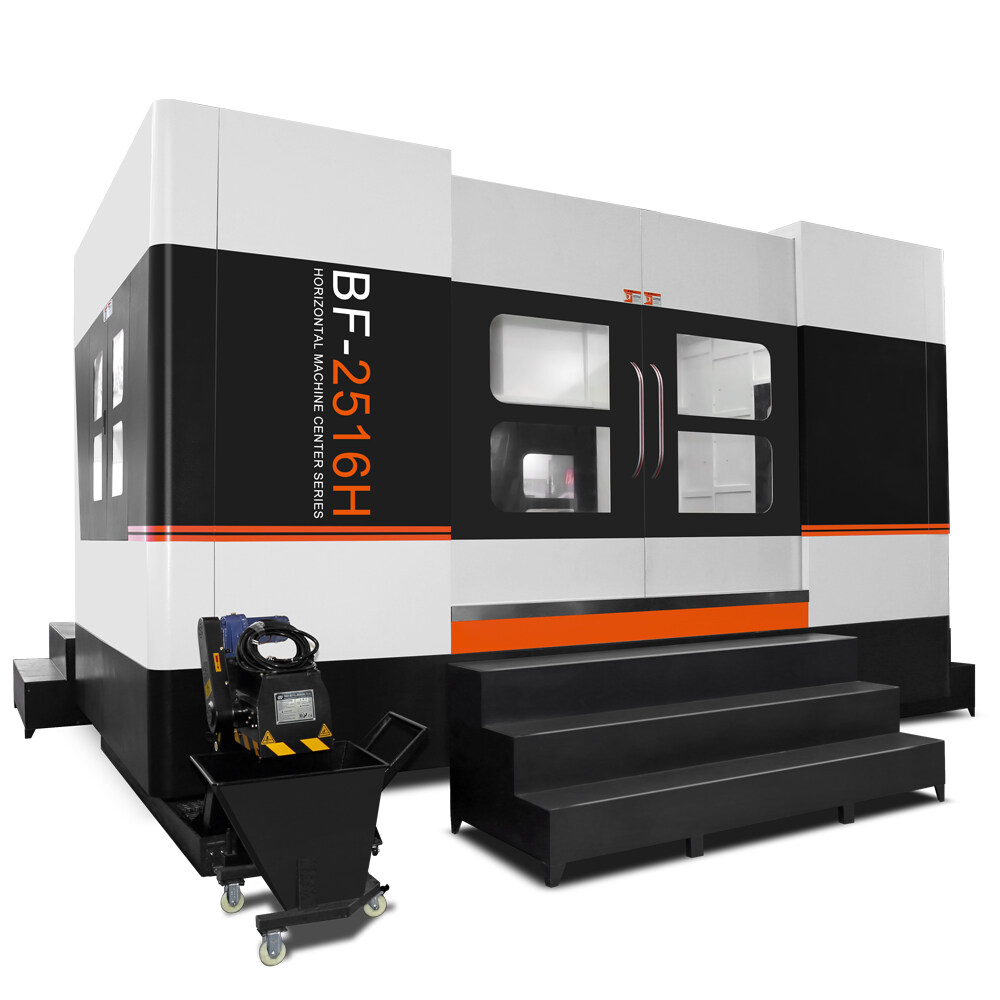

Horizontal Machine Center BK-2516H

With the use of advanced technology, our basic large parts adopt first-class research and development methods such as brand-new mineral materials, three-dimensional synchronous design, FEM finite element analysis, etc. We carry out a reasonable layout to ensure good anti-distortion and anti-bending ability of basic large parts