- NO63, XinTai Road, XinMaLian, DaLang Town, Dongguan City, Guangdong province

- info@baofengmachine.com

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

horizontal milling machine parts factory

Horizontal milling machine features

The spindle sleeve can be manually processed micro-injected and also has a limit device, as well as the milling head could be adjusted efficiently and left to right.

The worktable can be manually fed, horizontally and vertically and vertically down and up, while lateral and vertical manoeuvring can be carried out in vertical and horizontal directions;

It adopts an expanded lever of 1200 mm and an expanded table of 1500 mm. The longitudinal length of the table will reach up to 1000 mm, the line is long and the support is greater.

That both main drives, as well as the feed, follow a gear shift system, and the speed change range is wide;

Horizontal table milling unit uses

The spindle is of good steel and has a strong bearing capacity.

Worktable X, Y, Z 3-way motorized feed.

Features and Advantages of Horizontal Milling Machines

– A horizontal mill is a better option for complex projects than vertical milling.

– Horizontal milling machines usually have short and thick cutting tools.

– The spindle sleeve can be fed in a micro amount manually and equipped with a limit device. The milling head can rotate 45 degrees clockwise or anticlockwise.

– The worktable can be manually or automatically fed vertically and horizontally, and move vertically.

– The main drive and feed adopt gear speed change mechanism, which has a wide range of speed regulation.

– The spindle bearing adopts tapered roller bearing with strong bearing capacity and energy consumption braking, which has large braking torque, quick stop and reliable braking.

– The rectangular guide rail has good stability.

– The worktable and guide rail are quenched by super audio frequency, the strength is greater.

BAOFENG horizontal milling machine parts factory

horizontal milling machine parts factory, specializes in manufacturing horizontal media mills and other wet milling process equipment. We service and support all of our equipment and supply horizontal milling machine parts and premium parts for mills.

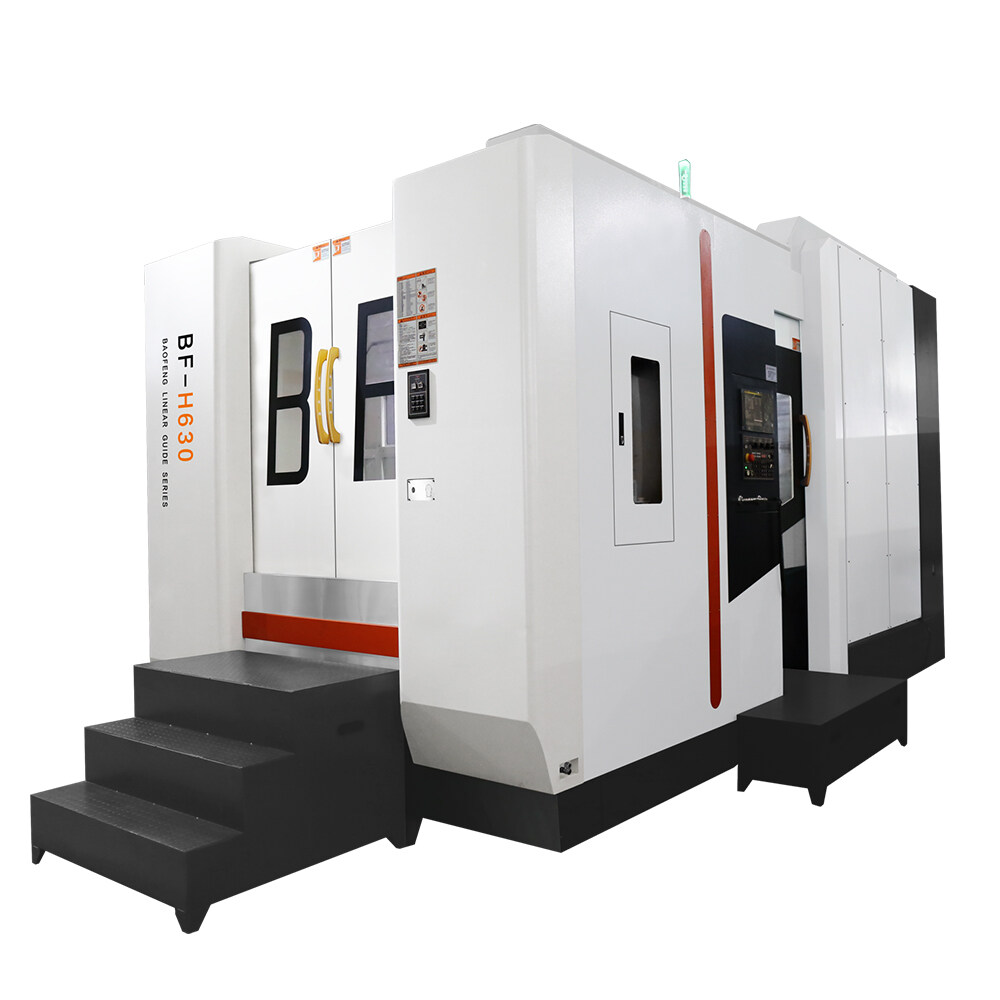

Horizontal Machine Center BK-1814L

The T-type base, full support structure for each axis, makes the machining accuracy more stable; Large capacity tool magazine and strong processing adaptability. Single and double exchange pallets are optional. Automatic chip removal reduces cleaning downtime. Wide processing range suitable for processing all kinds of mechanical parts

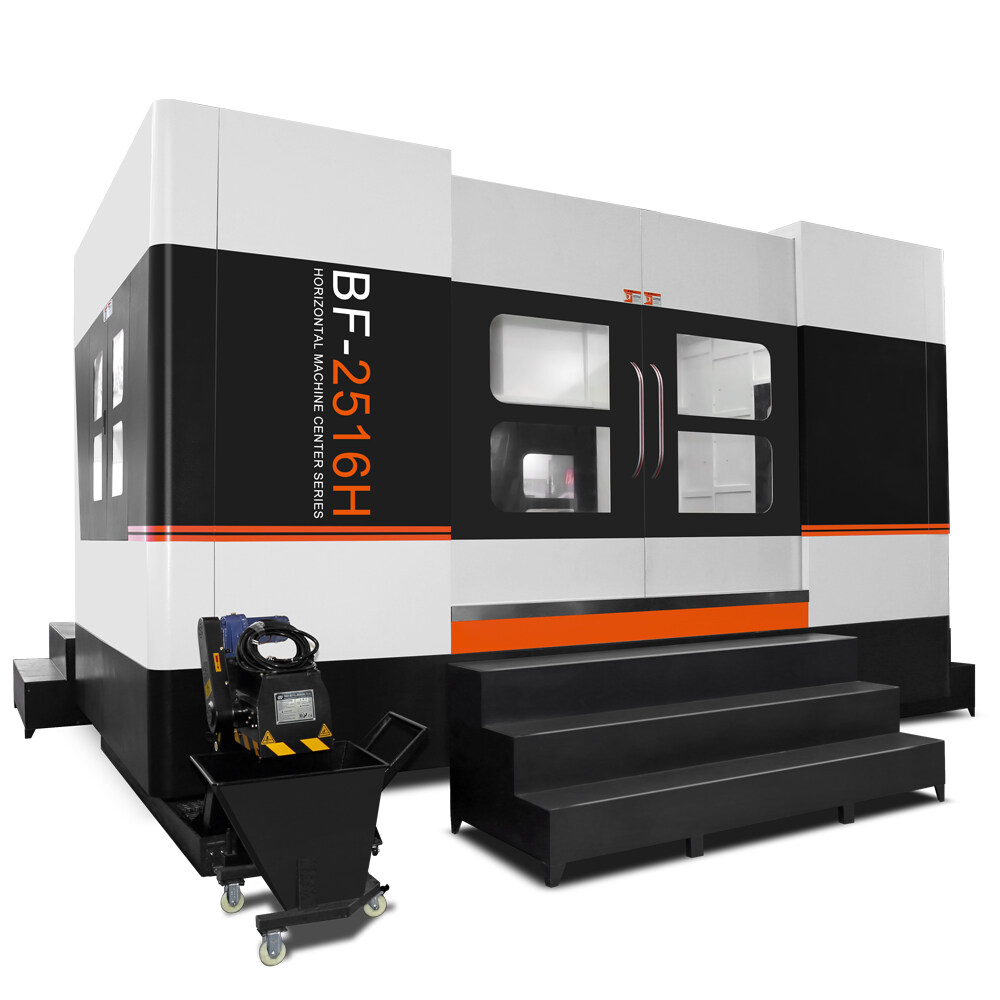

Horizontal Machine Center BK-2516H

With the use of advanced technology, our basic large parts adopt first-class research and development methods such as brand-new mineral materials, three-dimensional synchronous design, FEM finite element analysis, etc. We carry out a reasonable layout to ensure good anti-distortion and anti-bending ability of basic large parts